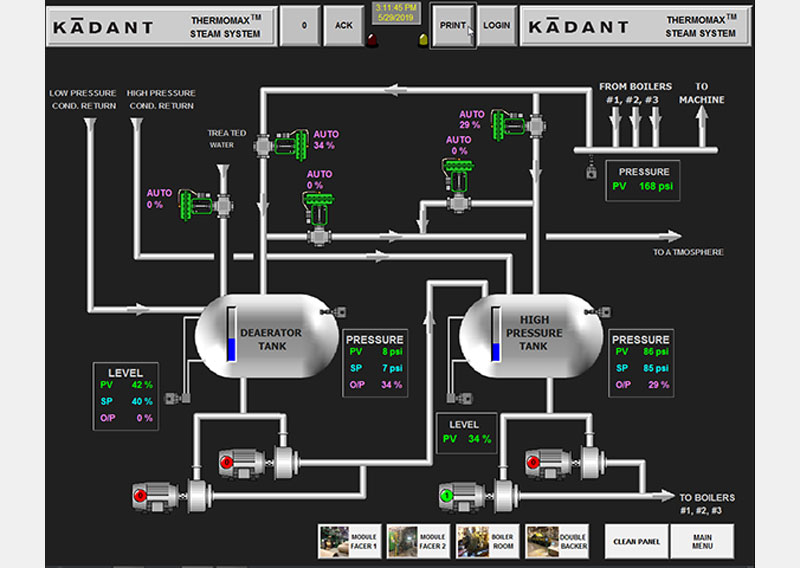

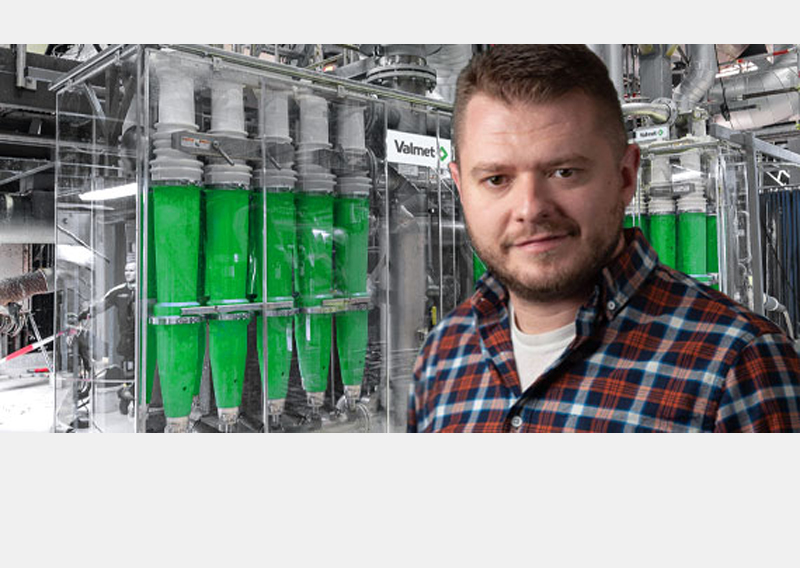

Proven ROI at a South U.S. Tissue Mill Using the RotoFlex™ Resource Recovery Strainer

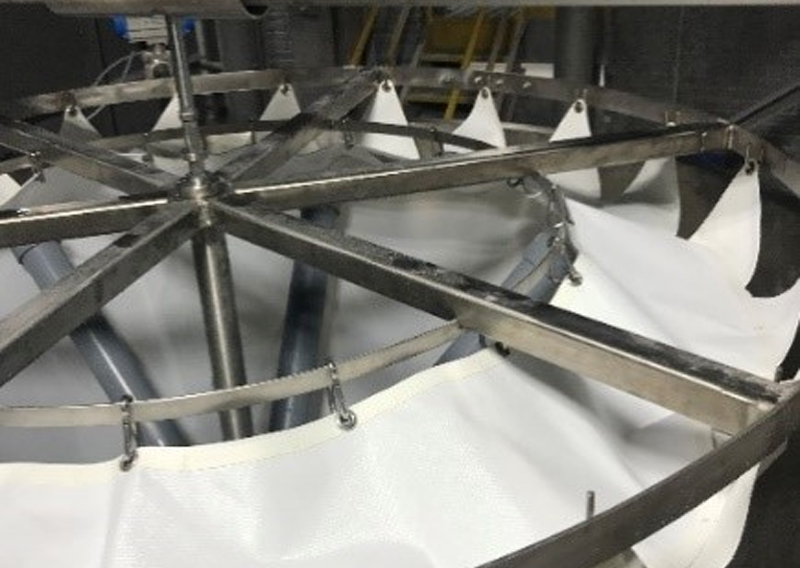

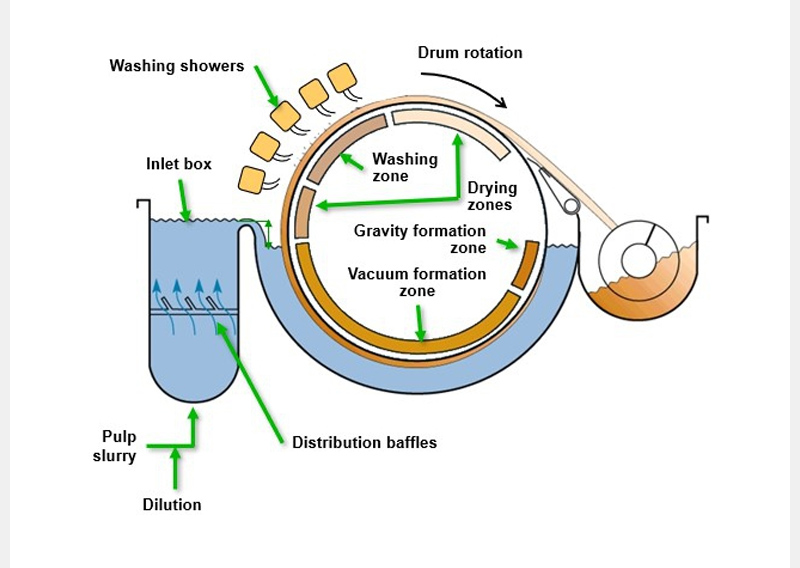

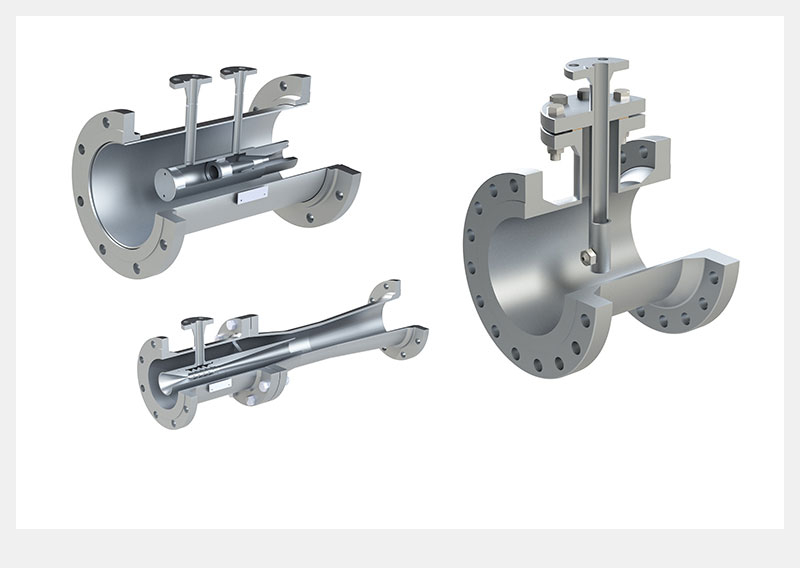

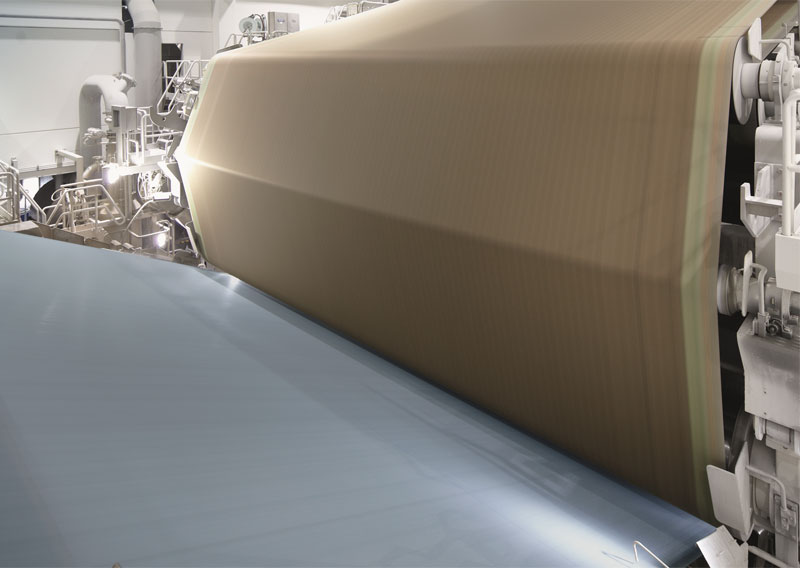

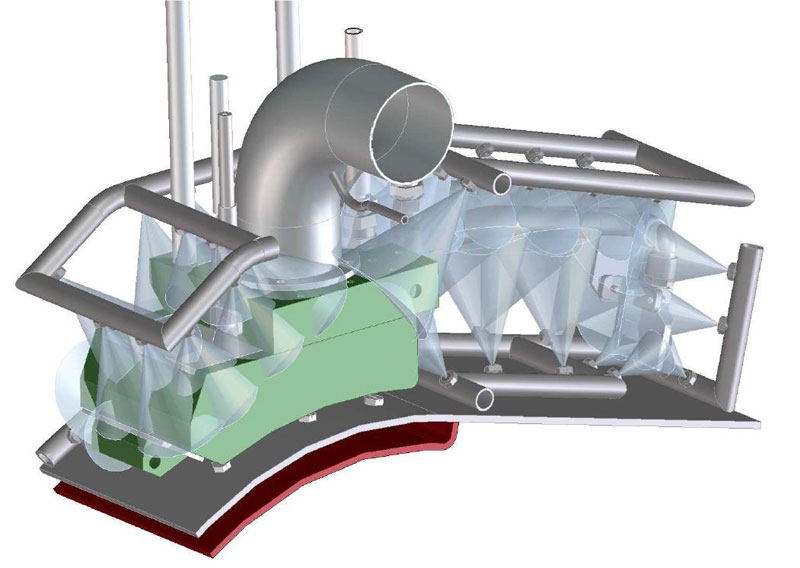

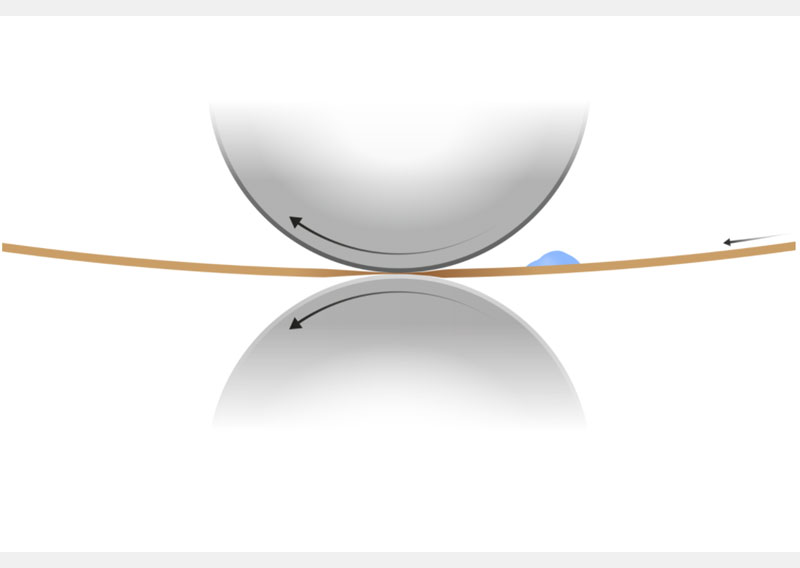

The RotoFlex resource recovery strainer is used to reclaim white water, heat, chemicals, and fiber effectively and efficiently from a variety of process industry applications.