In The Spotlight

DALLAS,

VANCOUVER, British Columbia, April 16, 2024 - Western Forest Products Inc. (TSX:WEF) (“Western” or the “Company”) today announced the indefinite curtailment of its Alberni Pacific Division (“APD”) facility, located in Port Alberni, B.C.

WASHINGTON – The American Forest & Paper Association (AF&PA) released its March 2024 Packaging Papers Monthly report.

WASHINGTON – The American Forest & Paper Association (AF&PA)released its March 2024 Printing-Writing Monthly report.

April 16, 2024 - Earlier today, Forest Products Association of Canada (FPAC) President and CEO Derek Nighbor released the following statement in response to the 2024 Federal Budget tabled by Deputy Prime Minister and Minister of Finance, the Honourable Chrystia Freeland.

In a significant strategic move, International Paper has announced its agreement to acquire DS Smith Plc, marking a pivotal moment in the packaging industry.

Recognising the importance of recyclability for the circular economy, Sappi has established a recyclability testing laboratory within its R&D Department.

In the realm of sustainable solutions, UPM emerges as a frontrunner, investing strategically in the biochemical industry. This move isn't just about business; it's a testament to their commitment to a future less reliant on fossil fuels.

Between 2012 and 2022, the number of people in the EU working in the manufacture of paper and paper products industry increased by 10.9%.

Feature Articles

Top Stories

DALLAS,

VANCOUVER, British Columbia, April 16, 2024 - Western Forest Products Inc. (TSX:WEF) (“Western” or the “Company”) today announced the indefinite curtailment of its Alberni Pacific Division (“APD”) facility, located in Port Alberni, B.C.

WASHINGTON – The American Forest & Paper Association (AF&PA) released its March 2024 Packaging Papers Monthly report.

WASHINGTON – The American Forest & Paper Association (AF&PA)released its March 2024 Printing-Writing Monthly report.

In a significant strategic move, International Paper has announced its agreement to acquire DS Smith Plc, marking a pivotal moment in the packaging industry.

April 16, 2024 - Earlier today, Forest Products Association of Canada (FPAC) President and CEO Derek Nighbor released the following statement in response to the 2024 Federal Budget tabled by Deputy Prime Minister and Minister of Finance, the Honourable Chrystia Freeland.

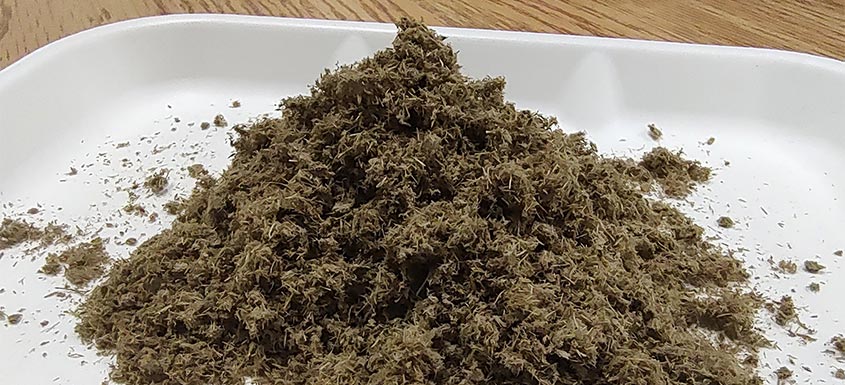

Cellulose packaging is booming. In recent years, we've seen the arrival - on the Quebec market - of cellulose packaging from other regions of the world.

With the ongoing momentum in corporate sustainability initiatives, the collaboration between pulp and paper companies and major corporations to create sustainable alternatives for their product lines is on the rise.

Sustainable forest management is essential to the Canadian paper packaging industry and its circular economy.

In a blog article last year, I wrote about the potential of high-temperature heat pumps (HT-HPs) to save energy in papermaking.

When looking forward at the forces that are likely to drive the direction of the pulp and paper industry over the next 15 years, decarbonization and supporting a circular economy are at the top of the list.

The new tissue machine is supplied by RePlus Tissue

The crush strength of the core refers to the capacity of a material to withstand pressure.

Corrugator operators run their machines based on data, experience, and conventional wisdom.

Valmet is taking process automation further by introducing the next-generation distributed control system (DCS), the Valmet DNAe.

Mondi Dynäs had experienced an unacceptable level of incidents for several years. Many traditional safety activities were initiated but did not translate to fewer accidents.

International technology group ANDRITZ is responding to the pulp and paper producers’ need to meet their process efficiency and environmental sustainability targets by launching a portfolio of intelligent instruments called the Smart Series at the Pulp & Beyond exhibition in Helsinki on April 11.

Green Bay Packaging proudly announces the promotion of Tom Short to Business Development Manager for National Account Sales.

Recognising the importance of recyclability for the circular economy, Sappi has established a recyclability testing laboratory within its R&D Department.

In the realm of sustainable solutions, UPM emerges as a frontrunner, investing strategically in the biochemical industry. This move isn't just about business; it's a testament to their commitment to a future less reliant on fossil fuels.

Time Tested, Future Forward: Celebrating Corrugated’s Storied Past and Bright Future