More vacuum alone may not be the answer

As Runtech forges ahead familiarizing North Americans with the brand, the company is showing how it can help mills improve their overall operating efficiency, thus saving water, energy and raw materials. And it is not just about new equipment, but also how the company can help a mill improve operations through its various service offerings including paper machine audits.

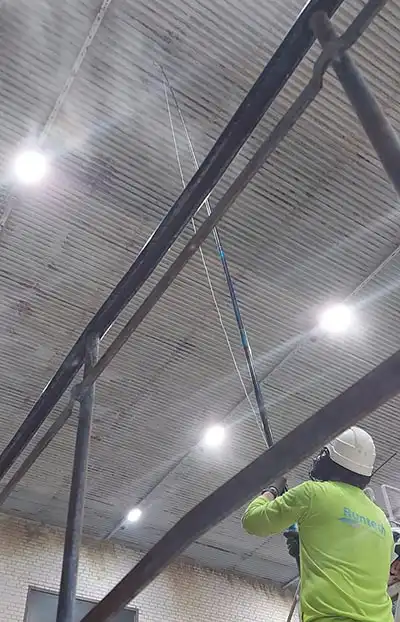

Known most for its turbo blowers, Finnish-based Runtech is now part of the Ingersoll Rand Gardner Denver family that includes Runtech’s former competitor Nash Pumps. Besides the pumps and blowers, the company also specializes in doctoring, tail threading, save-alls and pocket ventilation as well as its audits.

Water consumption is a huge concern for mills globally, perhaps more so than energy. Runtech’s approach is to audit, bearing in mind that each paper machine is different.

Although most mills will say that they want more vacuum, Runtech has found that this is often not the case. It will study a number of facets (e.g., uhle boxes, couch roll). It will also check the age of efficiency of pumps as they are often neglected and left to run year after year.

Air humidity measurement in paper machine hall

Air humidity measurement in paper machine hall

It will also recommend how to capture that water coming off the paper machine in different press positions: how well a mill is doctoring and capturing that water and measuring it. Many times, it will show that by decreasing vacuum levels, a mill can actually capture more water and achieve better solids out of the press section that by using high vacuum.

Many of the issues papermakers face deal with runnability. They may want to increase machine speed or add a vacuum pump. Runtech will go in and do a simple or in-depth audit. Other times a mill will have old equipment it knows that it needs to replace: for example, old blowers or liquid ring pumps with failing synchronous motors. In these instances, Runtech can devise a “game plan” for them.

As a “on-stop shop”, Runtech claims it can engineer, install and demo equipment. Engineering firms may be able to do it but it comes at a cost. In some cases, especially for a rebuild, a mill may not have a big budget; Runtech can help keep costs low.

It can be a wide range of parameters that need to be studied to develop a solution. Runtech will look at not only the pumps, but go all the way to the process area, e.g., machine geometry, dewatering and doctoring.

In one case, a mill coming out of a service was actually going “uphill” and damaging its low-vacuum fans. It was taking slugs of water through so Runtech looked at that.

Pocket humidity measurement

Pocket humidity measurement

For the audits, Runtech can do as little or as much as a mill wants. It tries to give a holistic view of how a mill stands from an energy view. Runtech has specific energy consumption charts for all paper grades so it can show how where a mill ranks globally. From this, a mill can at first look at picking the “low hanging fruit”, projects that can be done with little or no investment and then work outwards, always looking to help a mill achieve the biggest “bang for its bucks”.

The vacuum system is always the biggest hurdle and this will be included but it can be dome in a phased-in approach if a mill has specific issues it wants to deal with first.

A lot of companies in the liquid ring sector do not do this anymore, but Runtech is trying to be more pro-active, bringing the expertise back to the mills. This will help younger operating personnel bridge the gap of knowledge that has occurred due to retirement, the “silver tsunami: as it has been called.

Mills know when they have a problem and will be start with very specific requests. Often they will have had a consultant come in who will recommend action. Mills will take all this information they have and piece it together, but often they need help in deciding the proper direction to take.

In one case, a US mill was running with four obsolete pumps. Runtech did an audit and found that two pumps (not of the four obsolete ones) were running at a speed that did not produce vacuum, probably because their gearboxes had been changed. Runtech looked at a lot of things other than those four pumps and devised a game plan. It found couch solids could be increased by replacing the flatbox pump gearbox.

Although results are specific to each job, Runtech says typical horsepower savings can run 40-50%, which is significant. Some of this is installed overcapacity but better nip dewatering and measuring the flows coming off the PM will help a kill understand what’s really happening on the machine.

There still tends to be a “feel” sense in operating rather than a data sense. Runtech tries to put the data behind its findings to eliminate the feel. Again, it is part of the effort to have the mill really understand what it is doing on its machine. Ecoflow, online dewatering measurement system and good vacuum controls based on that will already help a lot.

The tissue sector is also one of Runtech’s strengths. Although operations differ from conventional paper machines, its approach to audits are consistent. The company has done will in the sector in converting mills from liquid ring pumps to blowers. It has also done well in equipping greenfield tissue mills.

Overall, the industry is spending more on capex. Conversions to brown grades and tissue still dominate, but this will peak in time. As energy consumption becomes more important, more capex can be expected in this sector. Water as well is a critical issue. There are two options: a dry system or a cooling tower. However, the latter is expensive.

In terms of sales, 2022 promises to be a record year for Runtech. Although the pandemic affected the company’s marketing efforts (as it did everyone), more projects are underway and more requests for quotes have been received.

Although traditionally seen as slow to accept new technology, North America is coming on board. Having the Ingersoll-Rand and Nash brands behind it does not hurt. Still, the company is showing that it is agile and able to maintain its engineered to order style.

It is an evolving market and Runtech sees its strength as being able to bring together both the liquid ring and dry systems along with paper machine components to make it an attractive option for customers.

It is not just in the “basement” anymore but on the operating floor as well understanding the full picture, helping production and maintenance personnel.

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Graeme Rodden has covered the pulp and paper industry for more than 40 years, including serving as editor of several well-known paper industry magazines.