I was first introduced to rice paper as a child when my mother baked almond macaroons. She would line a cookie sheet with rice paper, and when the macaroons came out of the oven, we ate the cookies with rice paper attached. The bits of rice paper left over dissolved on our tongues.

Some time later, my grandmother, on a visit from her home in England, used an expression to express her disbelief about something: “If that’s true, I’ll eat my hat!” My siblings and I proved she was wrong and made her a paper hat out of rice paper that she obligingly ate in front of us.

Some time later, my grandmother, on a visit from her home in England, used an expression to express her disbelief about something: “If that’s true, I’ll eat my hat!” My siblings and I proved she was wrong and made her a paper hat out of rice paper that she obligingly ate in front of us.

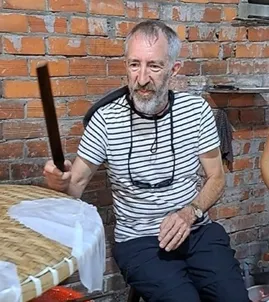

Earlier this year, I had the opportunity to learn the traditional method of making rice paper (bánh tráng) in Vietnam. It starts with a slurry of rice flour and water, which is spooned out onto a cloth stretched over boiling water. In this case, the water was heated by an oven burning rice husks, so the process was fossil-fuel free! A domed metal cover was placed over the cloth for a minute or so to accelerate gelatinization of the starch. I then removed the sheet of rice paper from the cloth using a metal knife and laid it on a bamboo mat, as shown in the picture. The wet paper was then lifted by its outer edge to transfer it to a second bamboo mat for air drying.

So is rice paper really paper? While rice paper looks like cellulose-based paper, the process reminds me more of making crêpes. Rice paper is primarily a starch film; there are no fibres present, so the paper is not very strong under stress.

Vietnam also has factories that produce rice paper. One of them is located in Tây Ninh province, not far from Hô Chi Minh City. The process, which involves a lot of manual labour to move the rice paper through the process and package it, includes a headbox, a wet felt, plastic panels that act as the “dry felt” and a steam-heated dryer section. The product is cut either into squares or circles and packaged onsite. This particular factory makes 1500 kg/day of rice paper.

Later on the day that I tried out traditional rice-paper making, I had the opportunity to use rice paper to make my own spring rolls and eat them. The rice paper dissolved easily in my mouth and the spring rolls were a tasty treat. I may start making my own spring rolls at home, but I don’t think I’ll try to make my own rice paper!

Martin Fairbank, Ph.D. Martin Fairbank has worked in the forest products industry for over 35 years, including many years for a pulp and paper producer and two years with Natural Resources Canada. With a Ph.D. in chemistry and experience in process improvement, product development, energy management and lean manufacturing, Martin currently works as an independent consultant, based in Montreal. He has also published Resolute Roots, a history of Resolute Forest Products and its predecessors over 200 years.

Martin Fairbank, Ph.D. Martin Fairbank has worked in the forest products industry for over 35 years, including many years for a pulp and paper producer and two years with Natural Resources Canada. With a Ph.D. in chemistry and experience in process improvement, product development, energy management and lean manufacturing, Martin currently works as an independent consultant, based in Montreal. He has also published Resolute Roots, a history of Resolute Forest Products and its predecessors over 200 years.

Martin Fairbank Consulting

Industry Experience

- Pulp and Paper Technology

- Biorefinery Development

- Government Subsidy Programs

Services

- Carbon Footprint Analysis

- Technical Writing

- Scientific Writing