As a mill’s equipment ages, producers are still faced with the issue of improving operational efficiency and perhaps increasing output to compete with growing competition while keeping costs under control.

Often, this could also mean a total mill conversion, for example, from newsprint to packaging grades. Or maybe just a change in roll width and/or diameter.

But, as technology evolves, how do mills integrate their legacy systems with this new automation technology?

The regional sales manager, northern U.S., for EPIQ Machinery, Andy Pienta, says the company saw an opportunity a few years back. At first, the focus was on the equipment from one of EPIQ’s predecessor companies, well known in the roll handling sector. Roll wrapping and ancillary equipment (winder decks) are still EPIQ’s forte.

However, its focus has widened, Pienta adds, as EPIQ realized it could help no matter what the customer’s legacy equipment brand. “We can go into a mill and do an assessment from a technical standpoint.”

Pienta says that as new technology evolved and markets change, mills are forced to “look inward” and be flexible. In other words, leaving their comfort zone. This could mean a new packaging process, increasing production or product conversion. “These are the main drivers for us.”

Often, a technological upgrade is needed. Some older systems are more than 30 years old. “We can breathe new life into the equipment,” he says.

Pienta adds that EPIQ itself has become more adaptable in solving issues. Not so long ago, old equipment had to be replaced. Now, EPIQ can install a new operating system that can extend the life of capital equipment, thus lowering capex.

One of the requests EPIQ deals with most often is for roll width increases. “Some mills have gone up to 132 in. from under 100 in.,” Pienta explains. Increasing capacity is another. “For each of these, we have solutions.”

Pienta cites one case of a converter that wanted to increase the size of the rolls it could handle. The challenge is that the roll wrapping process can be expensive, especially if roll throughput capacity is too low.

All went well with the project which took about a year to complete once the purchase order was received. There were some surprises along the way with some of the components of the aged machinery. “We set it up to be modular. There were a lot of manual interfaces before; operator training was required so they could handle the new system.”

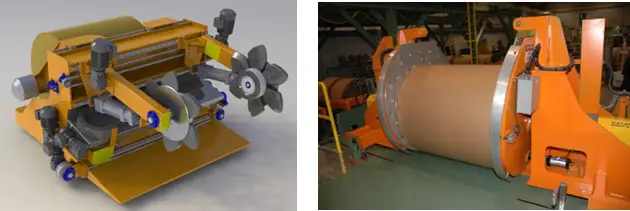

Using some of the legacy equipment, EPIQ supplied a new dispenser and backstands, creating a hybrid system that included modern controls and safety features. The mill had an oversized crimping station that could be used integrated with the new equipment.

Figure 1: Backstand, dispenser and crimper Figure 2: Header press

Figure 1: Backstand, dispenser and crimper Figure 2: Header press

“We were able to create an ergonomic arrangement for them,” Pienta adds. Once on site, EPIQ was able to complete the project in 10 days, while working in parallel with the existing operations. “In the end, we created a virtually new wrapping line.” It now takes just one person to maintain the line.

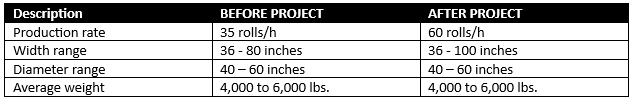

The project was planned for existing (35 rolls/h) and future potential (60 rolls/h), but Pienta says the main focus for the customer was the size of the roll. Normal roll width is now 60 in. diameter by 80 in. wide. However, roll width range is 36 to 100 in. while diameter can be from 40 to 60 in.

Table 1: rolls specifications and production rates

Table 1: rolls specifications and production rates

In this case, robots are not used in the process, but Pienta notes that EPIQ can supply and install them if requested, which helps with improving safety and can increase throughput. EPIQ has numerous “robot capable” technicians in their service and engineering groups. Robot solutions are especially unique, because of their ability to move in and out of the packaging system, originally designed with little space, and low headroom. “Those are our favorite projects.” adds Pienta.

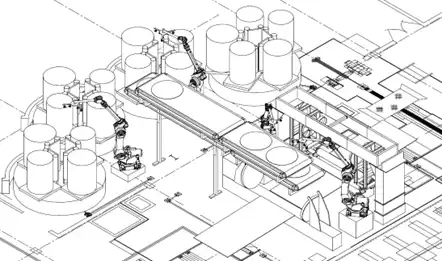

Figure 3: Mixed integration of old and new automation kraft wrapper layout

Figure 3: Mixed integration of old and new automation kraft wrapper layout

In another location, we were asked to implement more automation in existing legacy wrappers for the inside-outside head application. This upgrade also meant to increase safety at the plant by eliminating operators to interface with paper rolls during wrap cycle. EPIQ scope of supply was then to put in place two robots along with a header accumulation table. The header accumulation table can handle up to 5 stacks of predetermined diameters. Rolls diameters are measured upstream; robots get the information and are programmed to pick the right ones. Each robot tool handles 2 headers per cycle. EPIQ integrated the automation keeping previous crimper and header press, assuring good communication between the two systems: old and new.

Figure 4: Outside head robot Figure 5: Inside head robot

Figure 4: Outside head robot Figure 5: Inside head robot

As for controls, some opt to install a new PLC; others create their own systems. It depends on the client, but Pienta explains future upgrades are usually possible. Upgrades include control system hardware, safety system, programming or replacement components.

In conclusion, EPIQ objective is to help its customers to grow and adapt to market conditions by providing access to upgrades to legacy roll wrapping systems They provide their customers with the opportunity to incorporate additional technologies into their operations at a reasonable cost, rather than being compelled to operate with outdated equipment. It also facilitates the automation transition more smoothly than if the mill were to completely overhaul the system to implement a new, fully automated wrapping line. This approach is also applicable to pulper feeder handling solutions where EPIQ Pulp and Paper team can devise innovative solutions to increase your productivity.

EPIQ Machinery transforms heavy industrial material handling with intelligent, end-to-end Industry 4.0 solutions—seamlessly integrating automation, robotics, and digitalization. Merging the strengths of a technology innovator and a heavy machinery manufacturer, we deliver tailored, scalable systems.

Our client-centric approach ensures customized solutions backed by strong aftermarket support for lasting performance. EPIQ’s expertise spans mobile and fixed equipment, AGVs/AMRs, process systems, and smart automation.

We offer strategic analysis and recommendations for equipment upgrades, retrofits, and technology integration—empowering complex industrial operations to achieve greater efficiency, reliability, and innovation.

EPIQ Machinery, driven by its passion for challenges, shows strong leadership in the development of its own innovative technologies.

Learn more, visit: https://epiqmachinery.com/