The process of trimming is very important for papermakers.

It is often considered the number one cause of paper breaks on a paper machine. With proper maintenance, nozzle selection, and operating parameters, it can be simple to achieve a clean trim cut and reduce or eliminate paper breaks caused by improper trimming.

The purpose of trimming on a paper machine is to separate the formed edge and create a clean, precise edge. This allows the paper to be cut to the correct size for the product being run, but it also allows the sheet to run through the rest of the machine with less potential to break in the process.

To keep your trimming operations optimal, it is important to be mindful of several things. We’ll go through each of these items in more detail throughout this paper.

- Ensure the nozzles are not worn

- Higher water pressure produces a cleaner cut

- Run double orifices or double nozzles

- Angle the nozzles in the machine direction 10-20 degrees with the run, toward the dry end

- Angle the nozzles in the cross direction 10-30 degrees toward the edge of the machine

- Position the nozzles 2-6 inches above the fabric

- Position the nozzles after the suction couch on high-speed machines

- Examine the trim nozzle spray performance with a variable speed strobe light

A. Ensure the nozzles are not worn

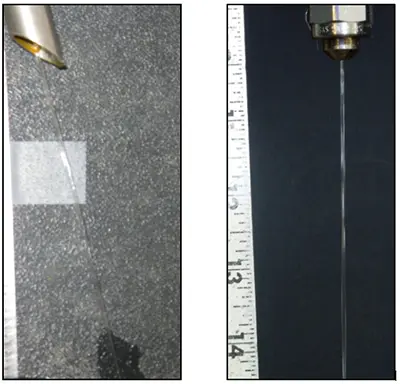

Starting off, it is important to make sure the trim nozzles are in good shape. If they are worn, the stream will degrade, and the cut will become inefficient. The pattern begins to break up before the stream has yet to hit the web and this can cause an irregular cut. When the pattern breaks up before the web, it starts to atomize, and you lose the “glass rod” appearance of the stream. The small particles coming off the stream also remove the stream’s impact force. This is what can cause irregular cuts and lead to a potential paper break, down the line. A good maintenance program to replace the nozzles regularly will help prevent issues due to worn nozzles. Premium materials, like sapphire or ruby orifices, extend the replacement cycle.

B. Higher water pressure produces a cleaner cut

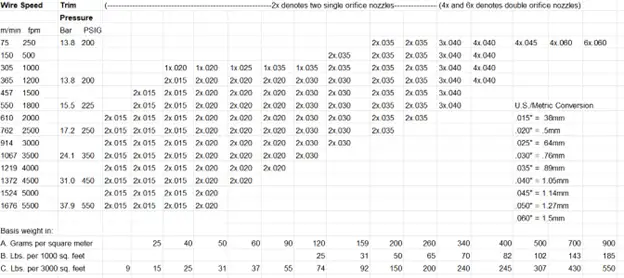

It is important to have the water pressure set properly. If the pressure is too low, the nozzle stream will not effectively cut through the web. If the pressure is set too high, this could cause issues related to splash back and cause damage to the wire the web lays on. Different paper weights will require different pressures and orifice sizes to properly cut through the web cleanly. When the water pressure is higher, it will create a higher impact stream and a cleaner cut. The table below offers trim nozzle orifice and quantity suggestions based on factors such as operating line speed, water pressure used, and the basis weight of the paper being produced.

Table 1: Trim Guidelines

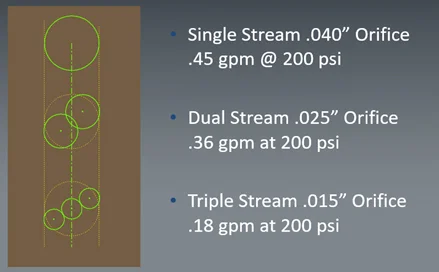

C. Run double orifices or double nozzles

Because trimming is such an important process, it is a good idea to either run double orifice nozzles or double nozzles for multiple reasons. Fresh, clean water in paper mills is a precious resource. Even though trimming nozzles do not require much water compared to other processes, it is still important to be mindful of the use of resources. When a double orifice nozzle is used, this can allow the use of multiple smaller diameter streams to be used. Not only can this produce a cleaner cut, but it will also reduce the amount of water required for this operation.

Figure 1: Options for a .040" Trim Cut

Figure 1: Options for a .040" Trim Cut

A reason for using double nozzles is simply redundancy. A second set of nozzle streams will provide redundancy for trimming in case of air bubbles in the water line or other interruptions in the primary stream. This helps ensure the paper will have seamless, clean trimming regardless. With clean trimming, the potential for a paper sheet break down the line is greatly reduced.

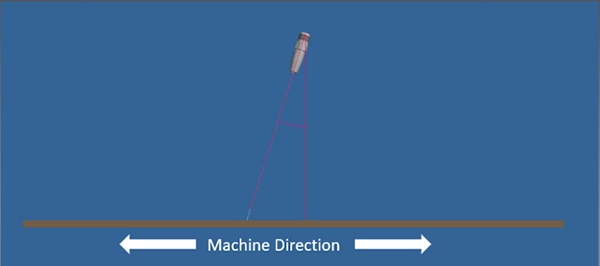

D. Angle the nozzles in the machine direction 10-20 degrees with the run, towards the dry end

Angling the nozzles in this manner is primarily to prevent any splash back from the spray hitting the fabric. Any splash back that does occur still, will settle back onto the web instead of causing buildup on the exterior of the nozzle. If splash back occurs onto the nozzle, there is great risk for debris to become attached to the outside of the nozzle and be a potential hazard. If enough debris builds up, it can fall onto the web and be a risk for a paper break on the machine. Nozzle design can be an important feature here. A nozzle with a beveled edge by the exit of the orifice can be positioned so any debris or droplets fall onto the broke of the trim instead of the usable paper web. When multiple nozzles are used for a trimming system, sometimes other anti-buildup measures should be taken such as air barrier adaptors or a misting nozzle to protect the stream and prevent buildup on the nozzles.

Figure 2: Tilt Nozzle 10-20 degrees with run, towards the dry end

Figure 2: Tilt Nozzle 10-20 degrees with run, towards the dry end

Figure 3: A typical misting setup for a multi-nozzle trim system

Figure 3: A typical misting setup for a multi-nozzle trim system

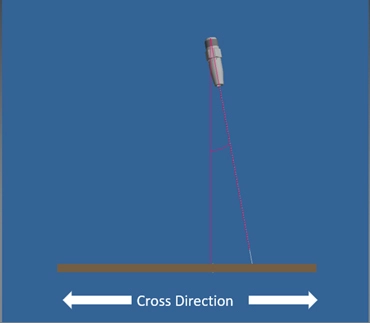

E. Angle the nozzles in the Cross direction 5-15 degrees towards the edge of the machine

When angling the nozzles towards the edge of the machine, this further aids in separating the broke trim from the main paper web. This helps to ensure the broke does not accidentally reattach itself after the trimming operation has completed. When the nozzles and pipes are angled towards the edge of the machine as well, it helps to focus any drops or debris towards the broke trim so they do not land on the web.

Figure 4: Angle the nozzle in the cross direction 5-15 degrees towards the edge of the machine

Figure 4: Angle the nozzle in the cross direction 5-15 degrees towards the edge of the machine

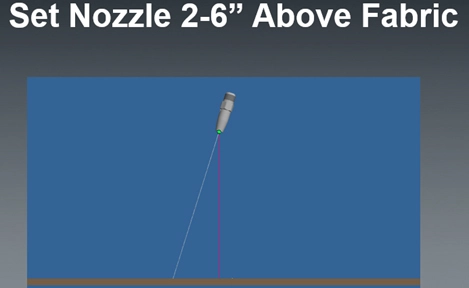

F. Position the trim nozzles 2-6” above the fabric

Picking the correct trim nozzle spray distance is very important. If the trim nozzle is too close to the web, this will result in significant splash back onto the nozzle and damaging the fabric. If the nozzle is too far from the web, the spray pattern will begin to break up which causes loss of impact and will not perform a clean cut. Every machine operates differently, and we typically recommend between 2 inches to 6 inches of spray distance depending on the setup of the machine. This will of course relate to the grade of paper being made, the pressure being run on the trim nozzle, and the speed of the machine.

Figure 5: Set the nozzle 2-6" above the fabric

Figure 5: Set the nozzle 2-6" above the fabric

G. Position the nozzles after the suction couch on high-speed machines

On high-speed machines, the water from the trimming process or couch suction roll can rewet the cut and allow it to stitch back together. When this happens, it can lead to paper sheet breaks and larger energy consumption during the press and dryer sections. By performing the trimming process after this, it is less likely to have the trim broke stitch back to the paper web.

H. Examine the trim nozzle spray performance with a variable speed strobe light

Strobe lights can be very useful tools to evaluate performance and adjust. They can be used in this case to examine the spray and identify the stream shape much easier than just using ambient light. Setting the light to approximately 50 – 60 Hz will allow observation of the quality of the spray. A laminar jet is the goal with trimming and there should not be any droplets or particles sticking out from the stream. It should look exactly like a glass rod. A turbulent jet would not look like a smooth, glass rod but have what appear to be droplets within the stream and a bumpy appearance. You could also potentially see twisting of the stream. A turbulent stream would exhibit breakup and loss of impact.

Figure 7: Laminar Flow Figure 6: Turbulent Flow

Figure 7: Laminar Flow Figure 6: Turbulent Flow

Summary

There are many factors which affect trim operations on a paper machine. Following these guidelines can help yield a reduction in paper sheet breaks, an increase in production up-time, and an increase in sustainable practices. Spraying Systems Co has been around for 85+ years and has the knowledge to optimize your processes. We would be happy to advise you and help you achieve your goals.

About the Author

Bernard Pyzdrowski is the project engineer for pulp and paper industires at Spraying Systems Co.

About Spraying Systems

Spraying Systems Co. is the world’s leading manufacturer of spray nozzles. Every day, our local spray technology experts help customers optimize operations and create more sustainable manufacturing practices. With tens of thousands of standard products, we have the right nozzle for your application – and we ship most standard products in one day. If you need a special product or material, contact us! We develop hundreds of custom nozzles, injectors and headers every year. Our engineering and manufacturing resources can help solve your toughest spray technology challenges.