In the pulp and paper industry, tank cleaning is often treated as a routine maintenance task—necessary but inefficient. Yet, with the right strategy, it can become a source of operational excellence. Here are five key approaches mills can adopt to transform tank cleaning from a bottleneck into a performance booster. Click to watch the video

1. Align Cleaning Methods with Operational Goals

Whether the priority is reducing labor, minimizing water usage, or accelerating turnaround during shutdowns, the cleaning method must match the objective. Many facilities still rely on manual pressure washing or fill-and-drain techniques, which are labor-intensive and inconsistent. Upgrading to dedicated tank cleaning nozzles can dramatically improve coverage, reduce water consumption, and free up personnel for higher-value tasks.

2. Select Equipment Based on Residue Characteristics

Tank contents vary widely—from water-soluble pulp to stubborn dried solids. Effective cleaning depends on matching nozzle type to residue behavior. High-impact nozzles are essential for removing hardened deposits, while low-impact options may suffice for lighter residues. Factors like tank geometry, internal obstructions, and cleanliness standards also influence equipment selection. For example, motorized nozzles may be ideal for broke chests, while reaction-driven models suit pigment tanks. For site specific recommendations, it would be best to reach out with details to your local spray expert.

Figure 2: Various Tank Cleaning Nozzles for Different Impact Requirements

Figure 2: Various Tank Cleaning Nozzles for Different Impact Requirements

3. Challenge the Assumption That Hot Water Is Essential

Hot water systems are costly and often unnecessary. By increasing mechanical impact through optimized nozzle design and flow rate, mills can achieve superior cleaning without heat. In many cases, chemical pre-rinses outperform thermal methods, offering a more sustainable and cost-effective solution. If steam is available during normal mill shutdowns, using a steam injector can assist with water temperature and pressure if hot water is deemed essential.

4. Prioritize Flow Rate Over Pressure

Contrary to common belief, doubling pressure yields only a 40% increase in impact, while doubling flow rate delivers a full 100% boost. Higher flow also improves throw distance, which is critical for large tanks and chests. However, excessive pressure can compromise stream integrity. The key is balancing flow, pressure, and chemistry to maximize cleaning efficiency.

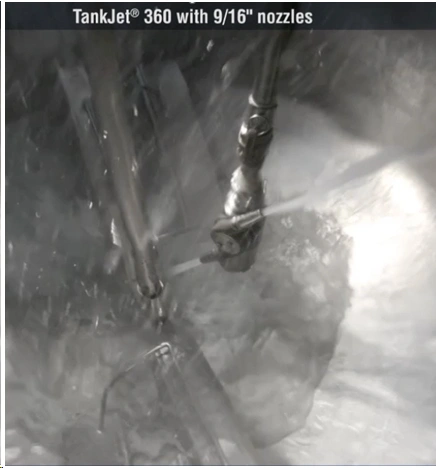

Figure 3: TankJet 360 Nozzle Operating at 75psi

Figure 3: TankJet 360 Nozzle Operating at 75psi

5. Reassess Legacy Systems and Upgrade Strategically

Tank cleaning needs evolve with production demands. Equipment installed years ago may no longer meet current standards. Wear, residue changes, and outdated specs can lead to inefficiencies. Regular audits and targeted upgrades—such as switching to a Cloud-Sellers® 360 Fluid-driven Tank Cleaner—can reduce cleaning time, improve safety, and enhance overall performance.

Case Studies: Efficiency in Action

- A paper mill cut water usage by 50% and reduced nozzle inspections from three times weekly to biweekly by switching to wide-coverage nozzles.

- Another facility eliminated confined space entry and slashed cleaning time from 12 hours to 3 by deploying high-impact nozzles, significantly improving worker safety and productivity.

Tank cleaning may not be glamorous, but it’s a critical component of mill performance. By applying these five strategies, facilities can reduce downtime, conserve resources, and elevate operational standards.

About the Author

Bernard Pyzdrowski is the project engineer for pulp and paper industires at Spraying Systems Co.

About Spraying Systems

Spraying Systems Co. is the world’s leading manufacturer of spray nozzles. Every day, our local spray technology experts help customers optimize operations and create more sustainable manufacturing practices. With tens of thousands of standard products, we have the right nozzle for your application – and we ship most standard products in one day. If you need a special product or material, contact us! We develop hundreds of custom nozzles, injectors and headers every year. Our engineering and manufacturing resources can help solve your toughest spray technology challenges.