In the pulp and paper industry, energy consumption and efficiency are not just buzzwords; they are the linchpins of sustainable and profitable operations.

The drying section of a paper machine is particularly energy-intensive, accounting for a significant portion of the total energy used in the papermaking process.

Runtech’s Drying Section Audit is a specialized service designed to scrutinize and enhance this critical stage, ensuring that papermakers can achieve optimal performance while conserving energy.

The audit process

A Drying Section Audit by Runtech is meticulous examination that begins with the environment of the drying section itself. By measuring pocket humidity and temperature, Runtech’s experts assess the conditions that can impact drying efficiency and paper quality. Similarly, cylinder surface temperature and sheet temperature measurements are crucial for understanding the transfer of heat to the paper, which is vital for energy conservation and effective drying.

The audit includes a comprehensive calculation of drying parameters, which form the backbone of any drying efficiency improvements. These parameters help operators understand the drying curve and identify areas where energy may be used suboptimally. The hood air system is also analyzed to ascertain if it is functioning at its peak potential, as any inefficiencies here can lead to energy waste and reduced machine performance. Mechanical checking is another important aspect of the audit. This step ensures that all mechanical parts are in good working order, which is essential for maintaining consistent drying conditions and preventing unexpected downtime. Additionally, heat recovery efficiency measurements are taken to evaluate how well the system is reclaiming energy, which can be a significant source of cost savings.

Drying Section Audit is a tool to improve drying capacity and runnability and decrease energy consumption.

Drying Section Audit is a tool to improve drying capacity and runnability and decrease energy consumption.

Runnability in drying section

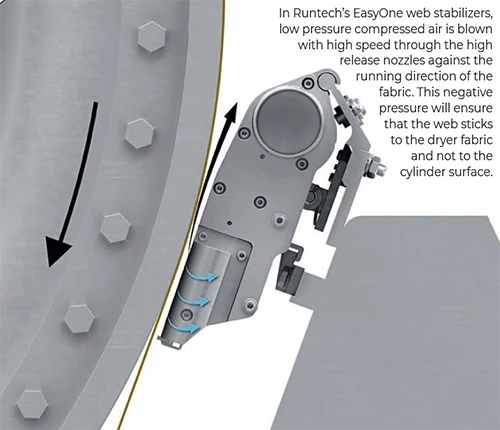

Runnability issues in the paper machine are influenced by multiple factors, all of which are carefully examined during the Drying Section Audit. In high-speed paper machines, the first single-felted dryer groups are particularly challenging to manage. The wet web, still fragile, tends to follow the upper cylinder without adequate high-vacuum support, leading to breaks and defects. Further reducing the draw in these sections improves paper quality and enables higher operating speeds.

One key challenge is the unsupported sheet draw, often found between the press nips or between the press and the dryer section. The movement of felts, fabrics, rolls and the web generates airflows and pressure differences that can lead to sheet flutter. By modifying roll geometry to shorten the open draw and optimize sheet transfer, these issues can be mitigated. This improvement enhances runnability, increases machine speed and boosts end-product quality.

Runnability challenges are even more common in double-felted areas compared to single-felted sections. Long unsupported sheet transfers increase the likelihood

of breaks. Shortening the unsupported draw by 25–50% between the top and bottom dryers facilitates smoother operation, including ropeless tail threading. Reduced pocket humidity and greater sheet wrap against the drying cylinders also improve drying capacity, supporting efficient and reliable production. Based on the drying section measurements, a simulation of the evaporation in the drying section is performed.

The simulation allows for calculating the adequacy of drying capacity and assessing the possibility of converting drying groups in the two-tier configuration to a singletier configuration until the paper has reached sufficient dry content and strength. In a single-tier configuration, drying is always easier in terms of runnability, but the drying capacity is slightly lower because only the top cylinders transfer heat to the paper.

The benefits of the audit

The primary benefit of a Drying Section Audit is discovering the improvement potential for runnability, as it can lead to fewer breaks and higher overall efficiency. The other benefit of a Drying Section Audit is the potential for energy savings. By identifying areas where energy usage can be reduced without compromising drying capacity or paper quality, papermakers can significantly lower their operational costs.

An audit can also extend the life of the drying equipment by ensuring that all components are operating correctly and not being subjected to undue stress or wear. This proactive approach to maintenance can helpavoid costly repairs or replacements down the line.

The outcome

Upon completion of the audit, Runtech provides a comprehensive report that includes a summary of findings and a detailed analysis of the drying section’s operation. This report is accompanied by tailored recommendations that are specific to the equipment and process of the client. These suggestions are focused on practical, actionable steps that can be taken to enhance performance and efficiency.

Implementing the recommendations

The implementation of Runtech’s recommendations is a critical step toward reaping the benefits of the audit. The report acts as a roadmap for making adjustments to the drying section, whether that involves tweaking operational parameters, upgrading components or modifying maintenance routines. Adopting these recommendations not only leads to immediate improvements in energy efficiency and machine performance but also sets the stage for ongoing process optimization.

With the insights provided by the audit, operators can continue to monitor and adjust their drying processes, ensuring that they remain as efficient as possible in the face of changing conditions and evolving production demands. The Drying Section Audit by Runtech is a comprehensive service that offers papermakers a clear path to enhanced drying efficiency and reduced energy consumption. By focusing on the specifics of the drying process and providing tailored recommendations, Runtech empowers operators to achieve a more sustainable and cost-effective operation.

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.