Boosting Energy Efficiency and Emissions Reductions in Paper Mills

Steam will not be decarbonized with existing technologies

20% of global carbon emissions are caused by industrial heat, and half of that comes from steam. At paper mills alone, steam production for drying paper products drives 80-90% of total natural gas consumption.

Manufacturers are committed to reducing emissions, but 99% of industrial steam still comes from fuel-fired boilers. These boilers have historically been the only cost effective option to generate steam. Alternative technologies like electric boilers, hydrogen, and renewable natural gas (RNG) cost 3-5x more than natural gas, and most industrial heat pumps cannot produce steam at high enough temperatures and pressures for use in manufacturing. The manufacturing sector urgently needs a cost-effective, low-emission technology for industrial steam production.

Skyven Arcturus steam-generating heat pump (SGHP)

Skyven Arcturus steam-generating heat pump (SGHP)

Skyven Arcturus: Leading the way in emissions-free steam

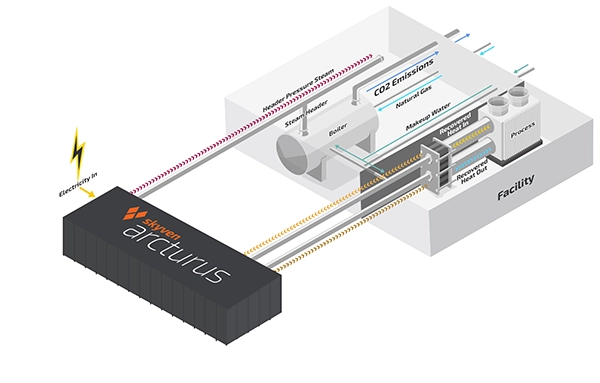

The Skyven Arcturus steam-generating heat pump (SGHP) produces emissions-free steam at the lowest cost and highest efficiency of any available technology. Arcturus electrifies steam production, leveraging high coefficients of performance (COPs) to generate emissions-free steam at a lower cost than natural gas boilers. It also enhances facility and grid reliability with a fully-redundant hybrid integration, seamlessly integrating with existing steam generation systems. Additionally, it uses 0 GWP water as its only refrigerant.

“By leveraging waste heat and its high-efficiency, Skyven Arcturus delivers cost-effective, emissions-free steam that seamlessly integrates with paper mills and other manufacturing facilities,” said Jim Saccone, SVP Global Sales at Skyven Technologies. “The future of industrial steam is here, and it’s cleaner, more efficient, and more affordable than ever before."

Unlike other heat pumps, Arcturus is capable of generating boiler-quality steam at temperatures and pressures up to 420F (215C) and 300 psig (20 Barg). To do so, Arcturus captures low-grade waste heat from commonly-available on-site heat sources, like paper machine exhaust, increases the temperature of that heat, and then uses it to generate boiler-quality steam.

Zero-downtime deployment with Energy-as-a-Service

Skyven deploys Arcturus at manufacturing facilities using an innovative Energy-as-a-Service (EaaS) model. In this model, Skyven funds, designs, and installs the Arcturus system, then provides ongoing operations and maintenance. Manufacturers pay no upfront capital costs, instead sharing the economic benefits of the project once Arcturus is operational. This model enables profitable, low-risk projects for manufacturing facilities, with no downtime or impact to operations.

Cost and energy savings for manufacturers everywhere

Arcturus helps manufacturers reduce Scope 1 carbon emissions while meeting their financial goals. At one pulp and paper facility in the Eastern US, Arcturus will reduce annual natural gas usage by more than 580,000 MMBtu, resulting in over 36,300 MT of avoided CO2 emissions. This is done with $0 CapEx required from the manufacturer and results in $1.9 million in average annual savings.

In regions with high-priced electricity markets, Arcturus still delivers substantial savings. At one West Coast facility, Arcturus will reduce annual fuel usage by more than 793,000 MMBtu, reducing annual emissions by over 42,100 MT. With a COP of 2.74 and a fuel-switching strategy leveraging existing boilers, the project will generate $919,000 in average annual savings.

Advancing steam, empowering industry

For paper manufacturers seeking cost-effective, low-emission steam production, Arcturus offers the most efficient, scalable, and financially attractive solution. With zero upfront costs, seamless integration, and proven savings, Arcturus is leading the way in industrial steam decarbonization.

About Skyven Technologies

Skyven Technologies decarbonizes hard-to-abate industries by recovering waste heat to produce clean, emissions-free steam using their Arcturus steam generating heat pump. Skyven’s proven Energy-as-a-Service model allows industrial manufacturers to achieve significant efficiency improvements and carbon footprint reductions without the upfront capital expenditure, leading to profitable decarbonization.

Headquartered in Farmers Branch, TX (near Dallas), Skyven is at the forefront of industrial energy transformation.

To learn more, visit www.skyven.co.