Pulp screening and low-consistency refining play essential roles in achieving the desired properties of paper, tissue and board. Screening and refining performance components can, however, be subjected to high levels of abrasive contaminants that will cause wear and compromise performance. Strategies to increase component lifetime are essential to enhance process stability, limit maintenance downtime and reduce overall costs.

Pulp screening and low-consistency refining are complementary processes in the production of high-quality paper, tissue and board. Screening eliminates oversize contaminants that would otherwise degrade the physical and optical qualities of the product. Refining applies mechanical energy to modify fiber properties and achieve the desired product qualities. In achieving these goals, screening and refining processes must also ensure sufficient capacity, high runnability, low power consumption, and minimal fibre loss / degradation.

Both screening and refining rely on highly-engineered performance components which have micro-geometries that are of critical importance. The processes are applied to a wide range of furnishes, including virgin kraft pulps, but in recent years and with the greater reliance on sustainability, there has been a shift to recycled furnishes such as old corrugated containers (OCC). Recycled furnishes typically come with higher levels of contaminants, which can include: light particles (i.e. styrofoam, plastics), large/heavy objects (rocks, bale wire), small/heavy particles (sand, grit, glass, metal fragments), “stickies”, and ash originating from filler and coating pigments. The small/heavy particles are of particular concern in wearing engineered performance components.

The most obvious consequence of component wear is the cost of the replacement piece. There are also the costs of shipping, storing and installing replacement components – as well as the related machine downtime. Process performance may decrease while the component wears, requiring adjustment of the process parameters. For all of these reasons, it is important to develop a multi-level strategy to reduce wear and increase component lifetime.

The strategy for reducing wear and extending lifetime is as follows:

- Preventative The removal of grit, sand and other small-heavy debris is accomplished by centrifugal cleaners, and settling tanks.

- Operational Operation of the equipment can be adjusted to minimize wear, such as by reducing speed to reduce the energy of the impinging particle (recognizing that impact energy varies as the square of velocity).

- Material Selection The application of a coating, or the appropriate selection of the component’s base metal, can increase wear resistance.

- Design In some cases the design of the component can be optimized to minimize the effect of wear on performance.

The application of these strategies is considered here in the context of pulp screening and low-consistency refining technologies. In particular, this paper presents some recent technical developments that have proven successful in a wide range of mill applications to increase equipment lifetime and reduce the problems associated with wear.

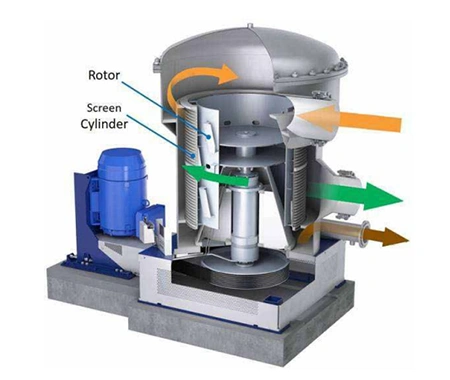

Figure 1. AFT MaxFlow™ HB Pulp Screen.

Figure 1. AFT MaxFlow™ HB Pulp Screen.

Pulp Screening

A pulp screen (as shown in Figure 1) is a relatively simple piece of equipment conceptually, but it is also a critical component in the stock preparation system. The development and operation of an optimal screen system, that not only removes contaminants, but reliably provides ample capacity, requires a high level of knowledge and experience. In fact, a mill may have several screen systems, with each system typically comprising several stages of screening. The key performance components in a pulp screen are the screen cylinder and rotor. The screen cylinder contains apertures through which the clean pulp flows, but which retain the debris. The rotor backflushes the apertures and creates flow conditions that ensure excellent runnability and capacity. The correct choice of rotor type, tip speed, and rotor-cylinder gap are critical to the performance of the screen application. The AFT MaxFlow™ HB Pulp Screen in Figure 1 shows the feed flow in orange, the clean "accept flow" in green, and the "reject flow" where debris is concentrated in brown.

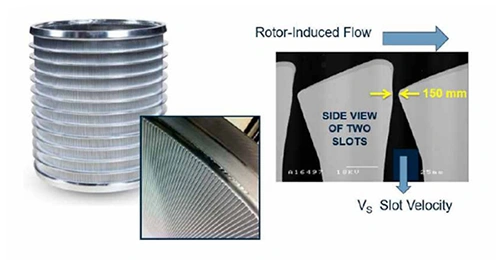

The apertures in screen cylinders may be in the form of holes or slots. The screen cylinder shown in Figure 2 is a slotted cylinder where the slots are defined by adjacent wedgewires. Figure 2 also includes close-up sectional view of a single wedgewire and the adjacent slot. The wire is seen to have a complex shape, which includes a surface contour that creates the necessary hydraulic conditions for ensuring screen capacity. Choosing the correct aperture type (i.e. hole versus slot), aperture size, wire width and contour height is critical to a successful screening application. AFT benefits from having the widest range of cylinder options in the industry and a proprietary wire shape which has been emulated by many other suppliers.

Figure 2. Screen cylinder (left);

Figure 2. Screen cylinder (left);

inside view (centre) and

sectional view of a screen wire and two slots (right).

Abrasive wear can impair screen performance in the following ways: Rotor wear will reduce pulsation / backflush strength and increase the cylinder - rotor gap, causing a decrease in screen capacity. Slot-type cylinder wear will cause slot width to increase, allowing more contaminants to enter the screen accepts. Contour-type cylinder wear will reduce contour height, leading to lower capacity and increased reject thickening (i.e. increased fiber loss). Cylinder lifetimes can range from 6 months in high-wear applications to 10 years for very clean furnishes, but are typically about 3 years for recycled furnishes.

Material selection is one of the aforementioned strategies to reduce wear. Cylinders have been traditionally manufactured from 304L or 316L stainless steel. Chrome plating is applied in abrasive environments when additional protection is needed. Alternative metals and surface treatments have been sought to increase sustainability, reduce the industry’s carbon footprint and save cost.

The AFT Shield™ Cylinder is designed for coarse screening applications and uses a wear-resistant “duplex grade” base material for additional lifetime. AFT’s DiamondWire® surface treatment represents the state-of-the-art in wear protection, providing a substantial increase in cylinder lifetime while avoiding the ecological impact of chrome plating.

LC Refining Technology

Low-consistency (LC) refining modifies pulp fibers while recognizing the essential trade-offs inherent in modifying paper properties, e.g. increasing strength at the expense of reduced drainage. The presence of highly-abrasive material within the pulp makes optimization of equipment and operating parameters even more complex as one considers refiner plate wear/integrity, overall operating costs and fiber development goals.

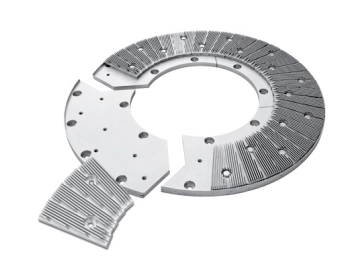

Figure 3. AFT Finebar® MiniSegmentTM

Figure 3. AFT Finebar® MiniSegmentTM

refiner filling with adapter plate.

The refiner filling (Figure 3), also known as the refiner “plate”, is the critical performance component of the LC refining process. AFT-Finebar refiner plates are custom-made for each application based on a detailed analysis of the furnish, refiner, process and customer objectives.

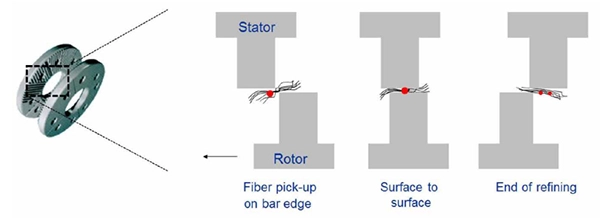

Contaminants can impact the refining process by plugging the refiner plate grooves or by accelerating bar wear. Wear rates in recycled pulp applications may be three to four times higher than for virgin pulp. Abrasives (e.g. ash, glass, sand, grit, metal pieces) can enter the refining gap along with the fiber flocs and are the major cause for accelerated wear (Figure 4).

Figure 4. Schematic illustration of abrasives

Figure 4. Schematic illustration of abrasives

(shown in red) entering the refining gap and that will abrade the refiner bars.

It is commonly accepted that “weaker” recycled fibers need gentler (lower intensity) refining to maximize strength potential. An increased concentration of abrasives in recycled pulp and the consequent short plate life have, however, hindered the pursuit of lower intensity refining. Groove widths of cast plates had to be fairly wide to minimize the plugging potential of larger contaminants. At the same time, bars had to be wide and tall to maximize lifetime. Wide grooves, wide bars, and tall bars are all contrary to the goal of maximizing the amount of bars and bar-crossings within a given refining area (i.e. “Edge Length” expressed in km/rev). The short lifetime of cast refiner plates in recycled applications also spurned the development of wear-resistant alloys such as “high chromium white iron” and “Ni-Hard” – which are hard, but brittle. The low ductility of these alloys causes the plates to be are especially vulnerable to severe damage when large-hard objects (e.g. bale wire or rocks) enter the refining zone. The plates may fracture and release sections of the bars. The detached bar-sections can then lead to a catastrophic failure of the plate by initiating fractures in other sections of the plate or in downstream equipment. Ni-Hard and white iron alloys are therefore limited to very coarse patterns, with wide bars, that do not provide good fiber development.

While more ductile alloys are well-suited to the manufacture of narrow bar, low-intensity plates, their lower hardness leads to shorter lifetimes. The more ductile alloys also tend to be more expensive. AFT Finebar refiner fillings have proprietary design features that reduce wear, maintain bar ductility, and provide low-intensity fiber treatment. The fabricated structure of these plates enables the design of an optimal groove shape. A strong, efficient, longlasting filling is the result.

OCC – Old Corrugated Containers

OCC is the largest and most challenging application in recycled fiber refining. OCC has an inherent variability in its character (i.e. fiber length, origin, strength potential, fines content) and the system configuration can make it difficult to detect the end-product quality improvements provided by improved refining. Increased lifetime is easier to document and is often used by containerboard producers to select refiner plates. The benefits of lower intensity can be considered not only by its impact on lifetime, but also through an inherent belief that it will benefit packaging product strength. The following case study was carried out in a Chinese linerboard (testliner) mill where the long fiber fraction of a Chinese OCC / AOCC mix was refined with two 34” double-disk refiners. The goal was to increase burst strength (i.e. “Burst Index”) without impairing drainage.

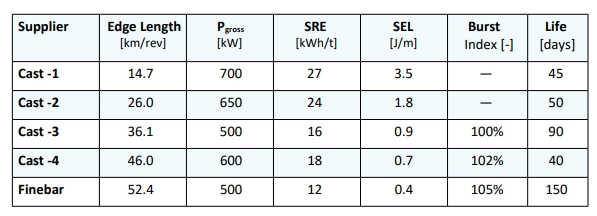

The results from tests with five plate suppliers are shown in Table 1:

- Tests with plates from the two incumbent suppliers (Cast-1 and Cast-2) were not able to achieve the threshold target burst values (given as a relative Burst Index = 100%) while respecting the drainage constraints.

- A test with the Cast-3 plates, with increased edge length, succeeded in achieving the Burst Index target. Lifetime was doubled.

- Cast-4 plates had additional edge length, and in this test additional power was applied (expressed either as gross power (Pgross) or Specific Refining Energy (SRE)). Specific Edge Load (SEL) was reduced because of the increased edge length. A 2% increase in Burst Index was obtained, but at the expense of lifetime, which was even less than obtained with the original Cast-1 and Cast-2 plates.

- A breakthrough in performance was achieved with the AFT Finebar plates featuring a much higher edge length, which gave the lowest values of SRE and SEL, and a 5% improvement over the target Burst Index. Gross power decreased by ~25% relative to the existing plates.

In the context of this paper, it is especially noteworthy to see the three-fold increase in lifetime: from 45-50 days with the existing plates to 150 days with AFT Finebar. Based on these results, the mill switched to AFT Finebar.

Table 1. Trial results at a Chinese testliner mill

Table 1. Trial results at a Chinese testliner mill

Summary

Pulp screening and low-consistency refining are complementary processes in the production of high-quality paper, tissue and board. Each is based on highly-engineered performance components that are subject to wear. Strategies have been developed to extend lifetime through prevention, changing the operational parameters, material selection and component design. The application of these strategies require an in-depth knowledge not only of tribology and wear mechanisms, but of the screening and refining processes.

With this expertise, increased lifetime may be achieved along with enhanced process performance.

About the Author

Jens Heymer (Ph.D.), Product Director - Fiber Development, AFT

Jens Heymer (Ph.D.), Product Director - Fiber Development, AFT

I became part of Aikawa Fiber Technologies in 2011 and now hold the position of Product Director - Fiber Development for the Finebar low-consistency (LC) refiner plate as well as conical filling business. In this position, I manage product development from conceptualization, design to production and launch.

Being involved in the P&P industry since 1996 provided the background and understanding that enables me to identify / prioritize product features that align with our clients’ needs and deliver measurable results in an ever-changing marketplace. I am very passionate about LC refining and creating innovative products that solve real-world TCO problems.