Applications of advanced diagnostic measurements in industrial settings are truly boundless. It's incredibly exciting to see how new instrumentation technologies can be adapted and applied in innovative ways, far beyond their original intended purposes.

The secret lies in embracing these tools with a spirit of curiosity and an openness to discover new potential from the measurement of previously opaque information. The underlying concept is called metrology - the science of measurement.

In this case, the length of the campaign, or run time between paper machine sheet-forming fabric changes (wire changes) was restored to normal using an instrument in a novel way.

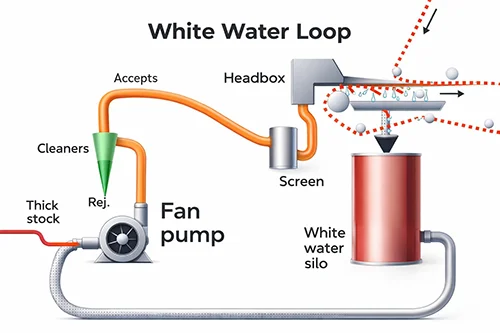

So here is what happened: The quite brilliant plant manager of a container board mill asked to use our rotary kiln burner spectrum analyzer over at the mill's brown-paper machine. We found that a fan pump pulsation was constructively interfering with other system components leading to wrinkles in the machine's forming fabric.

The phenomenon is well known in the industry, but the availability of highly powered sensors and software is rather new. Legacy instrumentation is heavy, expensive, and requires expertise to use properly.

The great thing about concentrating on pulsations, irrespective of the underlying mill system, is that the required equipment might already be present at a mill's location. The barriers to obtaining and employing sophisticated diagnostic tools have significantly decreased due to advancements in technology, and these tools might already be designed for use in other fields, but they may lie outside the typical toolbox and standard operating procedures of a particular organizational department.

By expanding the applications of instruments across different domains, and creating a mill wide listing of on-site diagnostic tools, an increasing number of companies can harness these technologies to foster innovation and operational superiority in their specific contexts. The master list of measurement tools seldom exists.

For instance, a common bearing vibration analyzer can be repurposed as a white water approach flow system analyzer by using some creative thinking. Without hesitation, mill personnel take the challenge of using their occupational tools in a novel way seriously. The best rise to the occasion as a chance to demonstrate their mastery of their craft. Besides, it's fun.

So, I would encourage every industrial company to approach its operations with a sense of curiosity and a willingness to explore new uses for diagnostic techniques by asking where your vendors and specialists might add value outside their normal lane. The opportunities to re-task analytical methods are there, waiting to be discovered. Who knows what other exciting applications we'll find as we continue to push the boundaries of what's increasingly possible with smart tools?

About Mike Ryan

Mike Ryan is recognized for enhancing operational reliability and efficiency, combining deep technical expertise with a strong focus on training and process improvement across a wide range of industrial settings.

Mike Ryan is recognized for enhancing operational reliability and efficiency, combining deep technical expertise with a strong focus on training and process improvement across a wide range of industrial settings.

He can be reached by email at