What is the gauge truly measuring?

Seal water flow monitors provide significant gains in water efficiency and seal reliability. The ESKO ESF monitor is designed for mechanical seal applications that require continuous cooling and lubrication. A pressure gauge is a popular add-on that is often mistaken for a supply pressure indicator ‘’– but here’s what it’s actually telling you.’’

Pressure Gauge Configuration Explained

The flow control valve (with an orifice) in a seal water meter creates a controlled restriction to maintain a steady flow to the mechanical seal. It ensures accurate measurement, consistent pressure, helping prevent excess water use.

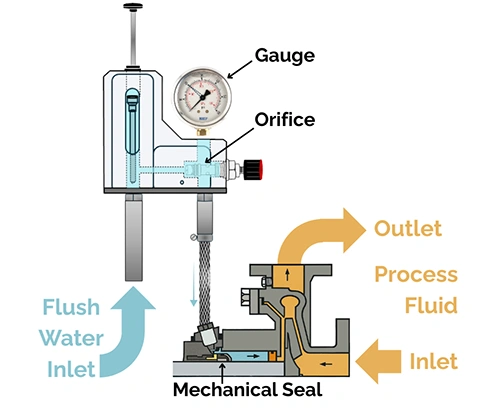

The pressure gauge is installed after the valve orifice, downstream of the flow control (see Diagram). It displays the pressure on the downstream side of the restriction or in other words, the flush pressure being delivered to the mechanical seal. For more precise seal water regulation, consider a dual flow seal water meter or an optional back-pressurizing valve.

Key takeaway: The pressure gauge is not reading the water supply pressure or the process fluid pressure. The gauge reflects the pressure delivered to the seal after the flow control valve restriction.

Diagram – Flush Water Schematic: Gauge and Orifice Placement on ESKO Model ES

Diagram – Flush Water Schematic: Gauge and Orifice Placement on ESKO Model ES

Optimizing Seal Water Flow

It is important to accurately control the supply of water into the stuffing box for effective water cooling and lubrication. The pressure gauge (in psi or bar) enables the operator to maintain a small, clean stream of water into the stuffing box.

If the flow rate reading is too low compared to the pressure inside the stuffing box, the clean water stream can slow or even reverse. This allows slurry or process media and grit to reach the seal faces, causing wear, leakage, and premature failure.

On the other hand, if the flow rate is too high, operators may be over-flushing. This wastes water and can dilute the product or disturb process conditions.

Once the process pressure established, setting the correct seal water pressure enables operators to minimize water consumption and excess runoff while maintaining optimal seal cooling and lubrication.

Interpreting Flush Loop Variations

Watching how the gauge responds to small valve or regulator adjustments provides quick diagnostic insight into the seal flush loop. A steady, predictable reading confirms proper flow balance through the control valve to the seal. Noticing sudden changes can indicate blockages, leaks, regulator issues, supply issues, or a gauge problem.

Remembering what the gauge is indicating as well as interpreting shifts in gauge behavior can provide valuable insights into flush-loop health, allowing operators to make appropriate adjustments to maintain consistent seal performance and reduced water use.

Read more about Seal Water Savings Tips here. For more information about processes that could benefit from dual flow seal water meters or back pressurizing valves, contact ESKO Pacific.

All ESKO seal water meters are fully modular, easy to clean, and backed by expert support. With over 40 years of experience supplying variable area flow meters, seal water monitors, and lubrication systems to paper mills worldwide, ESKO Pacific delivers dependable solutions built for long service life and measurable water savings. Need help selecting the right model for your application? Contact us today or explore our complete line of metering products at www.eskopacific.com.