The pulp and paper industry is undergoing significant transformation, driven by innovations that aim to improve sustainability, efficiency, and product versatility.

One of the most prominent trends is the shift toward biodegradable and sustainable packaging. As businesses and consumers seek alternatives to plastic, paper-based packaging solutions like molded pulp, barrier-coated paper, and even paper bottles are emerging as eco-friendly options. These innovations help reduce the environmental impact of single-use plastics while offering durable and practical alternatives.

Another game-changer is nanocellulose technology. This material, derived from wood fibers, is incredibly lightweight, strong, and biodegradable. Its versatility opens up new possibilities across various industries, from packaging to construction and even medical applications, providing a sustainable solution that combines strength with environmental benefits.

The push for recycling efficiency is also shaping the industry. Advances in deinking and fiber recovery technologies allow higher quality recycled paper, enhancing the lifecycle of paper products. This development is crucial as the industry continues to focus on reducing waste and maximizing the use of raw materials.

In the digital age, smart paper is emerging as a novel concept. By embedding digital technology such as RFID chips or conductive inks into paper products, manufacturers can create interactive packaging and anti-counterfeiting solutions. This fusion of traditional materials with digital innovation opens new doors for product tracking and customer engagement.

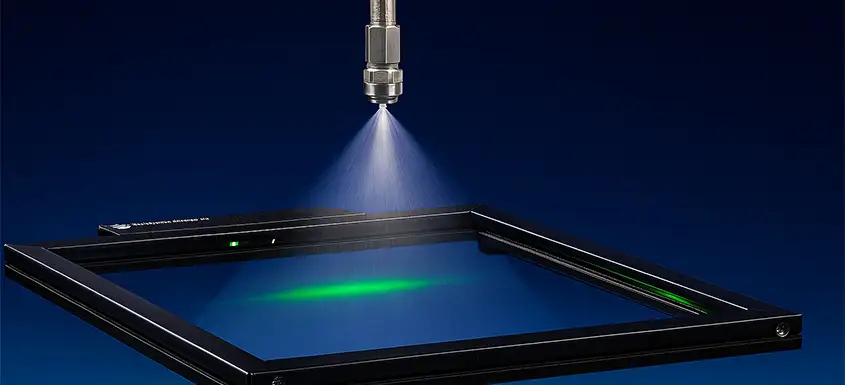

Water and energy consumption are major concerns for the paper industry, and water and energy-efficient technologies are making significant headway. Innovations like closed-loop systems in mills reduce water use and energy demand, helping to lower the industry's overall environmental footprint.

In terms of materials, bio-based chemicals are becoming increasingly popular. Derived from wood by-products like lignin, these chemicals are replacing fossil-based alternatives in coatings, adhesives, and inks, supporting a circular economy and lowering reliance on non-renewable resources.

Another innovation shaking up the industry is the use of 3D printing with paper pulp. This allows for the creation of intricate designs and shapes for packaging or artistic purposes, expanding the potential applications of recycled paper products.

The industry's digital transformation is further accelerated by the integration of AI and machine learning. These technologies enable mills to use predictive maintenance, improve quality control, and optimize production processes, leading to increased efficiency and reduced downtime.

Finally, some mills are striving for fossil-free production by adopting renewable energy sources like solar, wind, and bioenergy, as well as exploring green hydrogen for energy needs. This shift is part of the industry’s broader efforts to meet carbon neutrality targets and reduce its environmental impact.

In summary, the pulp and paper industry is evolving rapidly, driven by sustainability, digitalization, and efficiency. From smart packaging to AI-driven processes, these innovations are reshaping how paper products are manufactured, used, and recycled.