If you’ve walked through a lot of paper mills you’ve probably seen a lot of waste heat emitted. Most paper mills try to recover some of this heat using heat exchangers.

Heat exchangers work best when the hotter stream is significantly hotter than the colder stream. But what if you could concentrate a large warm stream into a smaller hot stream? That’s what a heat pump can do.

Heat pumps are common for domestic heating and cooling applications, but typically deal with temperatures between 0° and 60 °C. New heat pumps able to heat up to 200 °C are generating a lot of interest for application in pulp and paper mills as a pathway to lowering GHG emissions from fossil fuel, freeing up residual biomass for other purposes, or both. Heat pumps can upgrade thermal energy from waste heat sources and transfer it to ‘heat sinks’ using a small amount of electricity. Typically, the coefficient of performance (COP) of such heat pumps is 3 to 4, meaning that 1 kWh of electricity can produce 3 to 4 kWh worth of heat. That’s a pretty good return on energy use! If the electricity is free of GHG emissions and fossil fuel used for heating can be decreased, the economics can be attractive, especially if carbon credits can be generated.

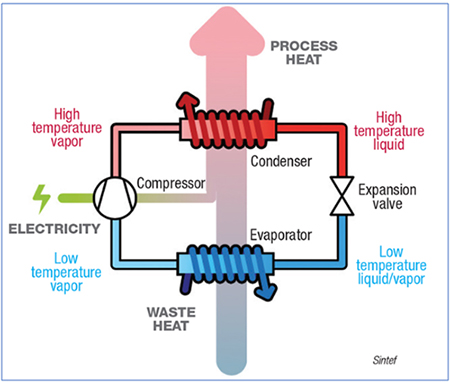

In a heat pump application, the transfer of thermal energy from the heat source occurs via a refrigerant liquid. Inside a heat exchanger the refrigerant turns into a gas. The gas is then compressed to a high pressure, causing a rise in temperature. This hot and highly pressurized gas then releases its heat into the ‘heat sink’, while the refrigerant turns back into a liquid as it cools. Its pressure is lowered, and the cycle begins again.

Heat pumps are already enabling energy savings for many industries. It has been estimated that there are potential energy savings in paper drying of more than 50%.

How would this be applied in a paper mill? One example is the transfer of heat from exhaust air at the dryer hood to the steam-heated cylinders in the drying section of the paper machine. After heat exchanging to pre-heat the incoming air feeding the drying section, the latent heat of the water vapour recuperated from the dryer hood can be used to evaporate the refrigerant in the heat pump. The refrigerant is then compressed to a liquid, and the resulting heat is used to evaporate the condensate coming from the drying cylinders. To lift the steam to a higher pressure, steam compressors are installed. Fresh steam from the boilers is added to ensure pressure control in the cylinders.

There have been several demonstration projects for industrial heat pumps in recent years, especially in Europe. In Canada, there is ongoing research led by Canmet ENERGY on high-temperature heat pumps for commercial, institutional and industrial application. With the world moving towards net-zero emissions by 2050, industrial heat pumps are expected to become mainstream in a few years and to be a big part of the solution for the pulp and paper industry – interest is heating up!

Martin Fairbank, Ph.D. Martin Fairbank has worked in the forest products industry for 31 years,

Martin Fairbank, Ph.D. Martin Fairbank has worked in the forest products industry for 31 years,

including many years for a pulp and paper producer and two years with

Natural Resources Canada. With a Ph.D. in chemistry and experience in

process improvement, product development, energy management and lean

manufacturing, Martin currently works as an independent consultant,

based in Montreal. He is also an author, having recently published

Resolute Roots, a history of Resolute Forest Products and its

predecessors over the last 200 years.

Martin Fairbank Consulting

Industry Experience

- Pulp and Paper Technology

- Materials Recycling

- Biorefinery Development

- Manufacturing

- Government Subsidy Programs

Services

- Technical Writing

. White Papers

. Grant Applications

. Explain technical concepts - Scientific Editing

. Review of articles for publication - Project Assessment

. Evaluation of Technologies

. Project evaluation for funding agencies - Pulp & Paper

. Conventional and emerging technologies