Vacuum systems are essential for papermaking as they contribute to sheet formation and dewatering, press performance, felt conditioning, and general machine efficiency.

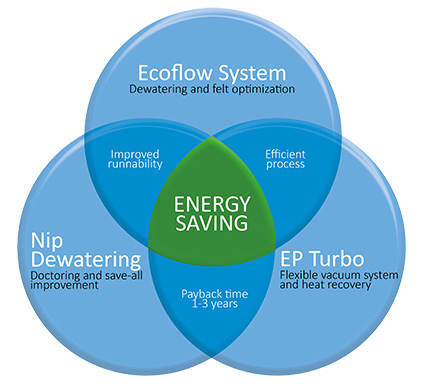

Understanding the dewatering process is the key to a wellworking vacuum system. Runtech’s main goal is to bring notable energy savings and highly improved process efficiency for paper mills.

Interview of Jussi Lahtinen, Sales Director for EMEIA and Americas, Runtech Systems

How did the story of Runtech Systems begin?

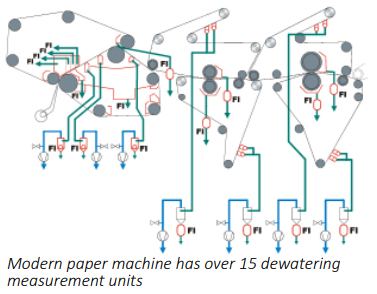

The history of Runtech Systems goes back to 1986 when the founder Mr. Juha Karvinen started to study and optimize paper machine vacuum systems. Ecoflow dewatering measurement system was developed as a tool to understand forming and press section dewatering and to show the papermakers that it is possible to improve total dewatering by reducing Uhle box vacuums. The first Ecoflow installations were done already early 90’s, way before the nip dewatering trend started. Now over 600 machines have been equipped with the Ecoflow system.

Runtech became a part of Ingersoll Rand corporation in 2018 (then known as Gardner Denver). In pulp and paper industry Ingersoll Rand is known for air compressors, wastewater treatment blowers, Nash vacuum pumps and Hibon blowers.

Runtech Systems is focusing on pulp and paper industry and our main solutions are vacuum systems, heat recovery, doctoring systems and water removal as well as runnability and tail threading products.

How did deeper understanding of dewatering effect on developing vacuum system further?

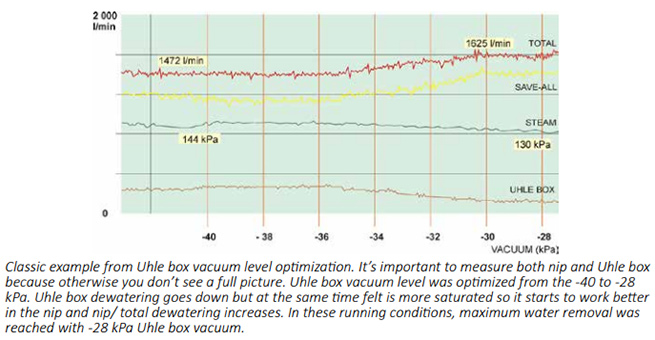

Once we started to understand the dewatering we realized that the vacuum system should be flexible. Paper machine conditions change all the time. For example, machine speed can easily vary from 200 to 1,100 m/min depending on basis weight and furnish, felt condition will change over its lifetime and it’s not optimal to have the same amount of vacuum (-kPa and/or air flow) for different conditions. During the past 30 years we have learned that it’s very important to be able to measure water removal and control the vacuum levels.

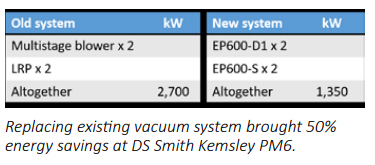

Traditional vacuum technologies were not good if the target was to optimize vacuum levels, minimize power consumption and adapt to the changing conditions. One very big challenge has always been the new machines, where machine suppliers play on the safe side and vacuum specifications are much oversized. If the machine is delivered with unsuitable type of vacuum equipment, the end customer has to live with that. In the worst cases we have rebuilt 3-4 years old vacuum systems reaching energy saving of over 50% or over 10 GWh/year. Unless you specify these things to your machine supplier they will deliver you the lowest cost option in terms of purchase price, not considering the life-cycle costs.

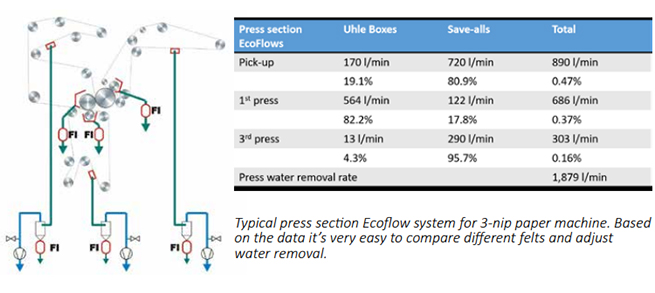

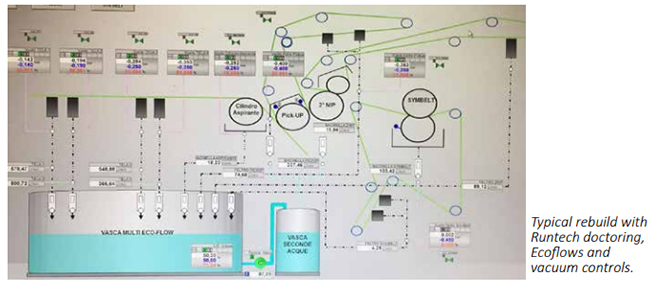

Our target was to make a dry vacuum system with variable capacity (air flow) and then give a possibility for the machine operator to select vacuum levels based on the actual need. So what defines the need? In case of flat boxes and Uhle boxes it’s most probably the water removal based on Ecoflows. In case of PickUp rolls it’s typically runnability and in case of press suction rolls it can be both runnability and dewatering. In many cases you want to have a slightly higher vacuum for the PU rolls when you PU the sheet, but after that the vacuum level can be normally reduced. This will give a big energy saving and can be automated as well. But if you have runnability problems with PU felt, you can easily ramp up the PU roll vacuums. Same goes with press suction roll vacuums. Typically, machine suppliers specify -65 kPa vacuums for press suction rolls, but in many cases, you don’t need so high vacuum. Typically for machines running less than 1,000 m/min -40...45 kPa is enough for the press suction roll. This difference is easily 100,000 EUR/ year. Again, an easy way to find the correct vacuum level is the online dewatering measurement system.

Runtech Turbo Blowers are always variable speed and capacity units. Integrated high speed motor is inside making the system very compact and easy to install. In most of the cases, we can replace the existing system with minimum piping and civil work costs. Big part of the installation is done during the normal machine run and only short shutdown is needed for the final connections. Our latest new machine projects in Europe are Propapier PM3, Hamburger Spremberg PM2, Palm Aalen PM5 and Mondi Ruzomberok PM19.

In normal rebuild cases energy saving is 40-60% compared to the old system.

One very good example is DS Smith Kemsley PM6, where the existing vacuum system was replaced by four Runtech Turbos and energy saving was 50%. Production Manager Stuart Ruck also highlighted that the new vacuum system allows them to start-up the felts in the optimal way and this has shorten the PU felt start-up period to 8 hours. This is of course extra production.

Mission to shut down Uhle boxes

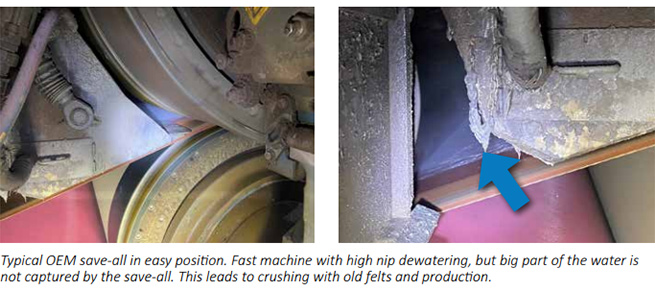

Forming/press section dewatering and doctoring is a big part of our energy saving solution. Water is removed in two places: Nips and Uhle boxes. If press roll doctoring is not perfect, Uhle boxes are needed. We try to build our doctoring so that with correct type felts customers can close the Uhle boxes. I think that we are the only supplier in the market thinking that way. You have to be able to see the situation without Uhle boxes, otherwise you just focus on the existing water amounts. Once again a good doctoring is designed to work together with the Ecoflows.

Especially for slower machines (< 600 m/min) it is critical to design the doctoring correctly because roll centrifugal force and water kinetic energy are low. Fast running machines are easier because water flies out from the press rolls automatically. Several of our customers are now running without Uhle boxes even machine speeds with heavier basis weights are < 300 m/min.

One very good example from this type of optimization is Smurfit Kappa Ania, Italy. Both PM2 and PM3 have been rebuilt and total energy saving in the vacuum system only is 9 GWh/year which equals to 700,000 EUR annual electricity saving. Additionally, production increased by 2% so payback time was approx. 1 year. Based on the Mill Manager Massimiliano Listi it was shocking to learn that how much vacuum they were using for nothing. For example, suction couch roll vacuum was stopped after forming section optimization. I guarantee that Ecoflows will open your eyes.

Why is nip dewatering so important for machines producing brown papers?

Brown paper machine production per meter width is normally fairly high. The most efficient machines are producing over 12 t/meter and this is very demanding for press section doctoring and water handling. High Uhle box dewatering would require a lot of Uhle box and vacuum capacity so this would not make lots of sense economically. Typically you need 20 to 40 kW/ meter (vacuum + press drives) to run one Uhle box so it makes lots of sense to close unnecessary boxes. On top of energy saving nip dewatering is also a very good way to improve total dewatering, reduce steam consumption, keep the felts open and improve cross machine profiles.

The role of felts

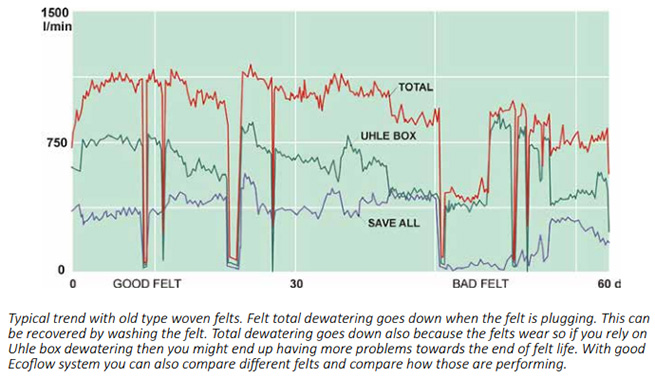

Felts can make a big difference in total dewatering and dryness after press but everyone should keep in might that nip dewatering is not possible without perfect doctoring. I have seen up to 3-4% improvement in press dryness when customers have optimized their felts.

Heavy woven felts can be difficult to saturate to right level especially if you don’t control the vacuum of Uhle boxes. It can be a challenge to keep high void volume felts open and in a good condition if you relay on Uhle box dewatering. Typically, with modern nip dewatering felts will give more stable dewatering conditions through the felt life and also facilitate faster start-up.

Towards smaller carbon footprint

At Runtech we think energy saving projects are bigger packages. It’s not only the vacuum pump or the Turbo Blower in the basement. Our target is to understand what happens on the machine levels and what might be wrong or different on the paper machine. During our machine audits we can study:

Vacuum system

- Press section doctoring

- Vacuum piping for possible pressure losses

- Forming and press section doctoring / water removal

- Forming and press section showers

- Dryer section exhaust system and heat recovery

Combining Ecoflows, press section doctoring and heat recovery to your vacuum system rebuild project will most probably shorten the payback time significantly.

Many companies have committed to reduce their CO2 emissions before 2030. 1,5 MW saving in the vacuum system saves average 4,000 tons of CO2 a year so vacuum system optimization projects are a very efficient way to reach these targets.

“Energy saving and dewatering optimization has been my passion for the last 15 years. Nowadays customers know much more about nip dewatering but it’s still nice to challenge them to do things in a different way. This is not an easy job, because normally papermakers are very conservative and not so willing to change 20 years old habits. After a project it’s very rewarding to see the results and these excellent references are helping us a lot in sales. I guess you just have to earn your customer’s trust!” - Jussi Lahtinen – Sales Director for EMEIA and Americas, Runtech Systems (on the right)

Runtech Systems is a Finnish-based company that develops, designs and supplies equipment to the pulp and paper industry. Hundreds of paper, tissue, board and pulp mills benefit from our dewatering meters, vacuum systems, tail threading equipment and doctoring solutions. Years of hands-on papermaking knowhow differentiates Runtech from traditional hardware suppliers. Our integrated solutions result in significant operational cost savings, improved machine runnability and product quality. Today Runtech is a part of Ingersoll Rand. www.runtechsystems.com

Runtech Systems is a Finnish-based company that develops, designs and supplies equipment to the pulp and paper industry. Hundreds of paper, tissue, board and pulp mills benefit from our dewatering meters, vacuum systems, tail threading equipment and doctoring solutions. Years of hands-on papermaking knowhow differentiates Runtech from traditional hardware suppliers. Our integrated solutions result in significant operational cost savings, improved machine runnability and product quality. Today Runtech is a part of Ingersoll Rand. www.runtechsystems.com