Cellwood Machinery's largest dispersing system is now in operation, at Bohui Papers facility in Shandong province China, among other locations.

Here, the Krima Disperser KD-1150 ensures the dispersion of recycled paper to the line, which currently claims the greatest capacity in the world – producing 2150 tonnes of white-top cardboard per day!

Bohui has worked with paper manufacture using established equipment and high technical expertise for many years and places great focus on scientific and technical research and development. The company's own research and development centre continuously works with new processes, which has led to increased production and greater market share.

High demands

The investment which was started in 2019 involved two new production lines, tasked with producing cardboard from recycled paper. One of the lines has the largest capacity in the world and can produce 2150 tonnes a day. The other has a capacity of 1500 tonnes per day. The large volumes, combined with the white surface coating applied to the cardboard, puts great demand on the equipment. The purpose of the investment was to minimise the number of dirty spots in the cardboard. The better the quality of the base paper, and the cleaner the bottom layer is, the less risk there is of contaminants bleeding through the white surface of the final product.

Good reputation

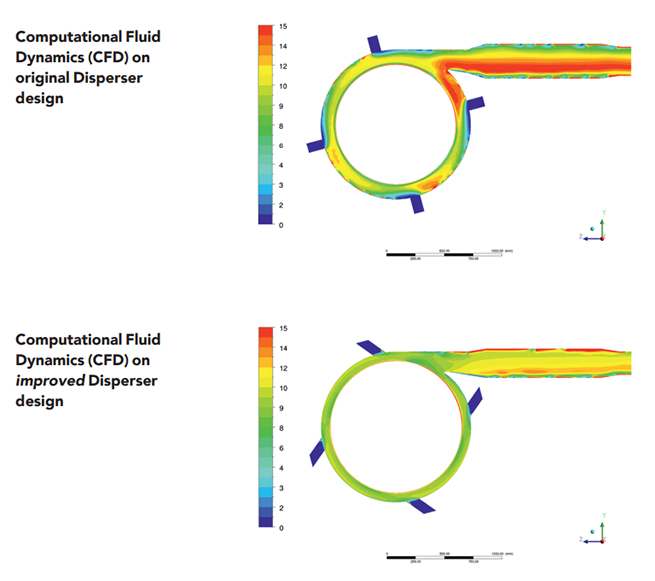

"We chose Cellwood Machinery because they have an excellent reputation within dispersing and because it meant that we had Kadant as main supplier for the rest of the line", says Mr. Zhou Tau, project manager. Cellwood Machinery supplied six complete dispersing systems, three of which were the new Krima Disperser KD-1150. The machine has significantly greater capacity than any of the company's previous models. Development of the machine included a large number of studies, simulations and flow analyses. The machine has been optimised to get through large volumes of recycled pulp and can be used in both new lines and in upgrades of older ones.

The lines at the Zibo paper mill came into operation during March and May of 2019, the employees at Bohui Paper are very pleased with both the collaboration and the equipment.

"After start-up we experienced huge benefits from the machines running smoothly", says Mr. Chen Qing Liang, and adds that production is running so well that the company very rarely has to conduct test measurements before and after dispersing. Within the next couple of years Bohui plans to start another major cardboard project, a line with the breath-taking capacity of 1 million tonnes a year, that is approx. 2,800 tonnes per day. This time however it is not about recycled paper, but virgin pulp, pure cellulose from the forest.

CM in China

Cellwood Machinery has been in business in China since the 1980s. The Chinese market started its impressive growth 20 years ago, and in 2008 Cellwood opened an office in Shanghai. Today the company has five local employees and over 200 installations sold to Chinese paper manufacturing companies. Bohui Paper is one of many new customers.

Cellwood Machinery has further developed its well-proven KRIMA Disperser.

The new Disperser design is based on Cellwood's world-leading models KD-450, KD-710 and KD-1050. Through extensive flow simulations and technical improvements, a new model, Cellwood's Krima Disperser KD-1150 has been developed. This work has now shown that the KD-1150 can produce up to 1100 Tpd with better energy efficiency and these improvements have been patented. Furthermore, it has been found that the fiber properties are developed to an even higher degree in the new design, this contributes to an increased efficiency in the stock preparation. With an upgrade kit one can, in a cost-effective way, upgrade an existing KD-1050 to get the benefits of the KD-1150 machine. Cellwood Machinery constantly strives to drive the development of Hot Dispersion forward. Improved efficiency and lower operating costs have been our focus since the early 1970s.

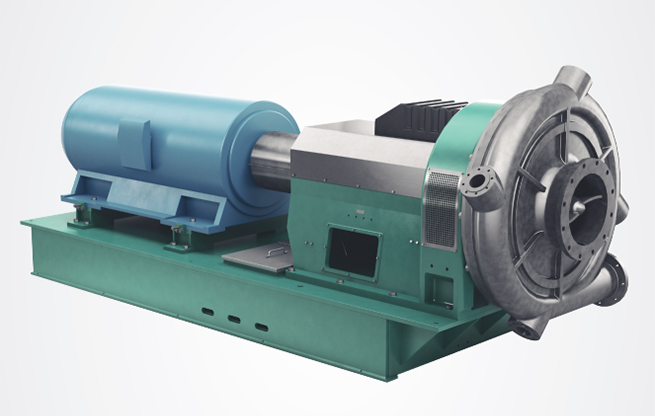

Newly developed Cellwood KD-1150 (patent pending).

Newly developed Cellwood KD-1150 (patent pending).

About Cellwood Machinery

Cellwood has played an important part in the development of the modern pulp and paper industry. The company is the world leading supplier of dispersing systems, which are used in the process of recycling paper waste into new paper. More than 700 system installations have been delivered to paper mills all over the world. www.cellwood.se