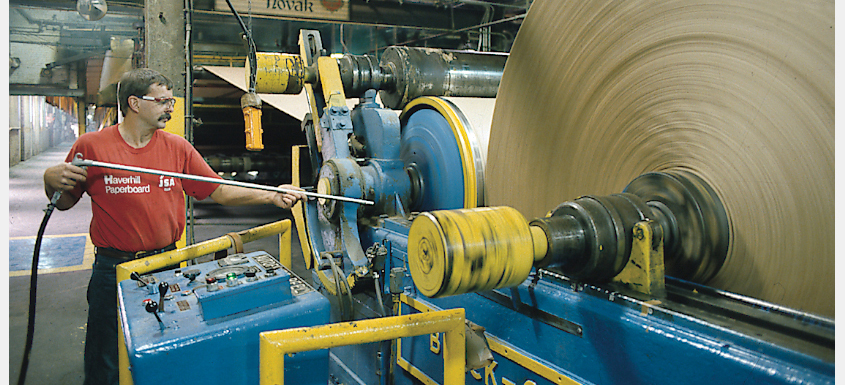

A widely used energy source in pulp and paper mills, compressed air is a very clean, effective, and efficient form of energy. It is so common that we tend to forget the risks associated with it.

Compressed air can cause serious injury and even death to its operator or to the people in the immediate vicinity; it is therefore essential to know how to reduce the risks.

Common risks

- Wherever compressed air blow guns are used for cleaning, there is a real danger of injury caused by particles ejected and blown into the surrounding air.

- Blown particles or objects can cause lacerations.

- Foreign particles may be blown into the eyes, which can lead to loss of sight.

- An air bubble can be injected into the blood and can cause a fatal embolism.

- Air blown into the mouth can rupture the esophagus or lungs.

- The residual pressure of a tool can be released when disconnecting the compressed air system resulting in disastrous consequences.

- Quick couplings – without zero-pressure disconnection – can cause dangerous lashes.

- Breakage of a pipe or pressurized air line can also strike like a whip and cause injury.

- Ball valves – non-lockable with constant downstream pressure when closed – do not allow equipment or tool repairs to be carried out safely.

- Noise generated by the operation of pneumatic valves can lead to permanent hearing damage.

Several consultants can perform a safety audit of a compressed air system.

"In fact, Topring is the only company to make compressed air its number one priority and to educate management, and employees about the dangers of the misuse of compressed air. We have developed a specialty niche in this field," commented Alexandre Ménard, Director of National Sales.

The primary challenge remains to target the right people, both managers and workers. "Safety must be everyone's responsibility.

A compressed air system must be, itself, properly padlocked and purged before carrying out an intervention or repair," insists Mr. Ménard.

Topring promotes PREVENTION and proper USE of compressed air.

There is also the energy saving component that must be considered. Compressed air often accounts for 10% of the electricity consumption in a factory; a comprehensive review of the compressed air system can identify leaks to be repaired and potential energy savings.

Compressed air use: The 12 rules of safety

What to look for? What to inspect? Awareness rules are all equally important and must be prominently displayed on a bulletin board in the workplace.

The 12 rules read as follows:

- Use compressed air only for the purpose for which it is supplied and, in the manner intended, and never exceed the recommended air pressure.

- Before using compressed air, inspect equipment, air hoses and fittings for damage (report any problems immediately).

- Do not allow air lines or air hoses to pass through high traffic areas (risk of tripping or breaking).

- Install a safety valve for each hose to avoid whiplash in case of hose failure.

- Never direct an airflow towards your own body or another person (including for cleaning, cooling, or joking). This can cause serious injuries. Never play around with compressed air (or pneumatic tools).

- Always wear appropriate protective equipment for the eyes, face and ears.

- Do not use compressed air to clean yourself, use a vacuum cleaner instead.

- Reduce excessive noise by using silencers and silent blowers.

- Keep air hoses clean, grease- and oil-free, and store them thoroughly with reels, away from heat sources and direct sunlight. Use hose reels to reduce the risk of injury and extend the life of air hoses.

- Before changing pneumatic tools or connecting pipes, close the valves and purge the air pressure. Use safe quick couplings with 2-step disconnection.

- Use self-purging and lockable isolation valves so that air pressure cannot be accidentally applied during maintenance.

- Never modify or install a safety relief valve whose pressure is greater than the nominal pressure of the pressure vessel to which it is installed.

There are many safety and prevention solutions for compressed air. To make sure you don't forget any of them, Topring has created a brochure that brings together all the different solutions. They are classified according to the problems related to compressed air. Each of the solutions will help you keep your employees, and your workplace safe. In this brochure, available on Topring.com, you will find a complete range of products for:

- Blowing and cleaning with compressed air

- Safe connection to the tool

- Prevention of lashes

- Preset valves and regulators

- Safe storage of air hoses

- Lockable shut-off valves

- Hearing health and noise reduction

- Air tool balancers

- Safe discharge of condensate

Focus on prevention and awareness to avoid workplace accidents. Contact Topring's specialists, they can offer you a multitude of safe solutions related to the use of compressed air. There are several simple solutions that are not always known, and that can make your work environment safer.