International technology Group ANDRITZ has received an order from ST Paper to supply a new tissue machine for its recently acquired site in Duluth, Minnesota, USA.

Start-up is planned for the end of 2022.

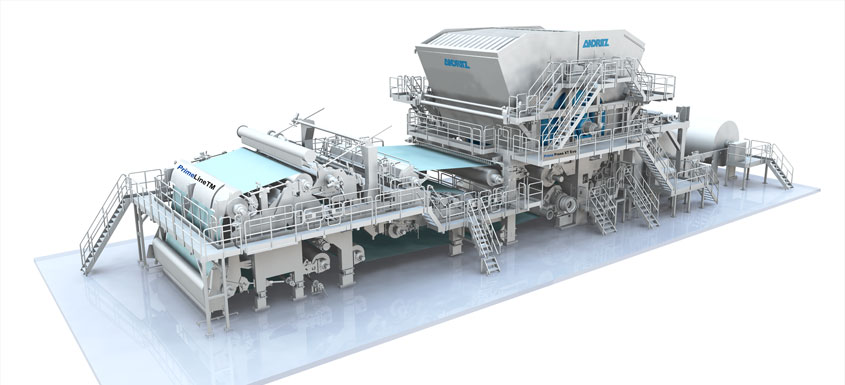

The ANDRITZ tissue machine of the type PrimeLineTM W 2000 has a design speed of 2,000 m/min and a working width of 5.65 m to produce a range of bath, napkin and towel grades. The order includes:

- the approach flow equipment with double dilution capability for excellent fiber preparation

- a fully cantilevered PrimePress XT Evo shoe press for gentle dewatering

- a 16 ft. PrimeDry Steel Yankee with head insulation, steam and condensate systems, and high-performance Yankee hood and process air systems for energy-efficient drying

- mist extraction and dust removal systems for safe operation and

- a PrimeReel standard reel with turn-up equipment for excellent end product quality

The entire production line will be equipped with an ANDRITZ PrimeControl MCS automation system which includes extended features for process automation throughout the tissue line and minimizes the number of subsystems and associated interfaces. Installation advisory services, start-up and commissioning services are also included in the scope of supply.

Sharad Tak, founder and principal partner of ST Paper: "We partnered with ANDRITZ because they offered state-of-the-art tissue machine technologies with a focus on optimized energy consumption and a commitment to achieve our project goals.”

Joseph Guadagno, ANDRITZ Vice President Tissue and Air Systems, North America, adds: “We are very pleased that ST Paper selected ANDRITZ as a trusted partner. The relationship developed with the ST Paper team on past projects contributed to this success”.

ST Paper acquired Verso Corporation’s idled Duluth mill in May, with the intention to convert the mill’s production from specialty paper grades to tissue. ST Paper has already successfully converted two fine paper machines into tissue machines at its Franklin, Virginia facility. ANDRITZ was a key supplier to ST Paper on both PM 5 & PM 6 rebuild projects at the Franklin mill, with the supply of the Yankee hoods and complete air systems for both rebuilds, including one of the widest Yankee hoods in the world at 8.43 m (332”) hood width installed on PM 6.

This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the North American tissue industry and ANDRITZ’s expertise specifically in wide tissue machines and energy-saving components.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Source: ANDRITZ