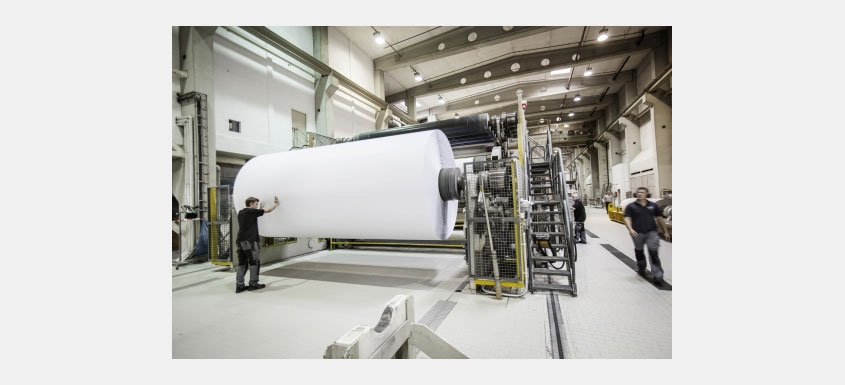

DREWSEN SPEZIALPAPIERE has successfully implemented the second step of a 2-stage rebuild-concept to PM5, with an upgrade of the pre-drying section which has made a significant step towards improving over-all productivity.

WAfter the installation of a smarnip shoe-press, completed in 2019 as part of the first step of a performance increase concept, further improvements of the web-run and drying capabilities of the pre-drying section were executed during Phase 2 during the summer shut-down in 2020.

ALLIMAND, a French paper machine manufacturer, together with its German representative FIPPTEC, defined the improvement concept and implemented the installation of four new stabilizing boxes with corresponding vacrolls, and the required modifications to the hood and ventilation systems.

These steps now enable faster and more secure tail-threading, more robust web-runs with less web-breaks, and the chance to maximize full manufacturing capabilities and increase capacity for most of the grades manufactured on PM5. All trial runs showed a marked improvement in the performance of the machine with good runnability and product quality.

With this investment DREWSEN has taken another important step towards expanding its market position for Thermal base papers, Thin printing papers, Label papers, Barrier papers for food packaging, and moreover, papers manufactured to replace plastic.

Learn more about DREWSEN’s Competence Center on https://www.drewsen.com/en/the-company/technical-equipment

Source: DREWSEN SPEZIALPAPIERE