Runtech Systems delivers RunEco vacuum system rebuilds to KleanNara tissue machines TM3 and TM4 in Chungcheogbuk-do, South Korea.

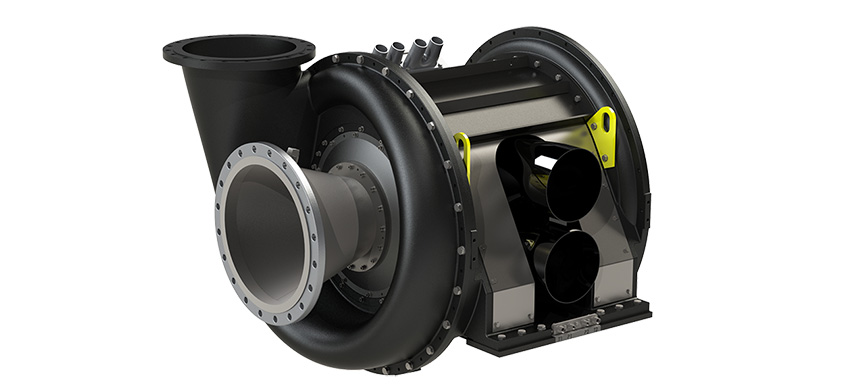

Deliveries include RunEco EP500 Turbo Blowers with EcoDrop water separators and EcoFlow dewatering measurements.

“With this repeat order KleanNara shows again their confidence in our technology. KleanNara has been using Runtech turbo systems successfully on their two board machines and the newest tissue machine already for years,” says Hannu Kääriä, Sales Director, Runtech Systems.

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About KleanNara

KleanNara is engaged in manufacturing of specialized paper products and hygienic products. Hygiene business is engaged in manufacturing and distribution of toilet paper, facial tissue, kitchen towel, diapers and sanitary napkins. TM3 and TM4 produce together annually approx. 40,000 tons of consumer bath grades on Cheongju Daehan site, North Chungcheong, South Korea.

More information:

Hannu Kääriä, Sales Director, Asia-Pasific;

Read more about RunEco solution https://www.gardnerdenver.com/runtech/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Source: Runtech Systems