Originally published in the May/June issue of Paper360°; www.paper360.tappi.org

Chromatogeny is a unique barrier technology that offers customizable performance for packaging that’s also repulpable and compostable. Could it become the ‘new standard’?

All packaging companies and brands want to drastically reduce their use of plastics and harmful chemicals and increase paper use. Indeed, many of them have committed to do so within the next five to 10 years. Yet, until now, there was no real viable, competitive, scalable, and truly sustainable solution available.

A new patented process answers many of these requirements and opens a new world of sustainable possibilities not only for the paper and packaging industries, but for others such as construction and health care. Overall, the serviceable market may be worth hundreds of billions of dollars. The technology has been developed by Cellulotech, based in Vancouver, BC.

WHAT IS CHROMATOGENY?

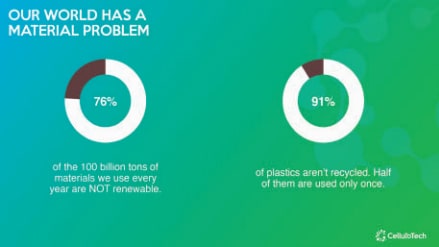

Simply stated, the world has a material problem. Of the 100 billion tons of material we use every year, 76 percent is not considered “renewable.” Half of our plastic materials are used only once, and 91 percent of plastics are never recycled (Fig. 1). We need to drastically reduce our reliance on such materials, and cellulose has a crucial role to play since it is the most abundant and renewable organic compound on Earth. Hence, Cellulotec seeks to decouple its value.

Figure 1.

Figure 1.

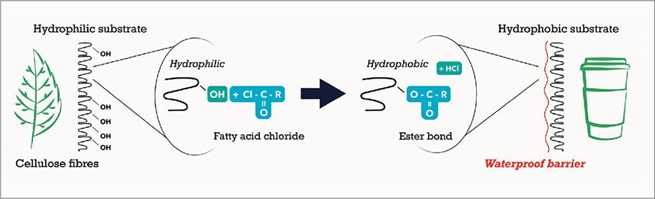

Chromatogeny is a green chemistry reaction (meaning no solvent is required) that grafts long-chain fatty acids onto a cellulosic substrate’s OH (hydroxide) groups. It is considered a nanotechnology, since it grafts a molecule as small as one nanometer over the whole specific surface. However, even if you can’t see or feel it, the performances are impressive. Treated paper becomes superhydrophobic without affecting breathability. Contact angles of almost 180 degrees can be reached, which makes paper behave like lotus leaves.

An overview of the technology. Solid Solid Partition Chromatogeny (SSPC) is a patent-pending process based on an innovative chemical engineering approach. It treats the reagent as a nanometer-thick monolayer film, which allows coverage of up to 50,000 m2 with only one kilogram. It also improves the grafting efficiency and considerably speeds up the reaction.

An overview of the technology. Solid Solid Partition Chromatogeny (SSPC) is a patent-pending process based on an innovative chemical engineering approach. It treats the reagent as a nanometer-thick monolayer film, which allows coverage of up to 50,000 m2 with only one kilogram. It also improves the grafting efficiency and considerably speeds up the reaction.

Researchers also discovered that, when grafting paper coated with polyvinyl alcohol (PVOH), they could get the excellent oxygen and grease barrier qualities of PVOH while offering a strong water barrier and a good vapor barrier as well. This can be achieved while preserving all the repulpability and compostability properties of paper and PVOH.

Grafted monocomponents are nothing new, but they were typically complicated and costly to manufacture. Cellulotech brings to the field an entirely new chemical engineering approach that allows extremely high speed and low cost. The process can apply as little as 20mg per square meter of an already widely available reagent. Overall, it can treat up to 50,000 square meters for just a few dollars. Moreover, Cellulotech’s process is not limited by a roll-to-roll approach since it can treat some 3D shapes or even corrugated cardboard. When we saw that by applying reagent on only one side we were also treating the flute and the other side, we were astonished.

Chromatogeny allows manufacturers to adjust the barriers to optimize the performance/cost ratio by playing with different parameters such as the substrate, the reagent, or the process itself. Regarding the substrate, there are infinite types of paper and a whole family of PVOH that offer very different performances once grafted. Cellulotech is also working on very promising bio-based substrates. Regarding the reagent, the change in performances can be exponential when the fatty acid chain length is increased.

One enemy of sustainability in packaging is overengineering. Overall, barriers need to match the actual needs and shelf lives or use time as closely as possible. Without sacrificing functionality, manufacturers need to optimize resources and minimize their environmental impact. This leads to two initial questions: What barriers are really needed, and for how long? What is the lowest cost possible that can be achieved adjusting the two parameters mentioned here?

Let’s take a paper cup, for example. There is no need for a thick layer of high-performing PVOH or the fatty acid with the longest chain available to get the performance needed for a few minutes of use. In contrast, flexible packaging is much different, as the barrier requirements are much more demanding. There are also products when only a strong water barrier is needed, but manufacturers end up using plastic, waxes, and other harmful chemicals because of the lack of satisfactory solutions. With the same process, chromatogeny allows them to be both selective and flexible regarding the barriers they provide.

A RANGE OF APPLICATIONS

The applications are numerous. At Cellulotech, we are confident that the more people learn about chromatogeny, the more ideas emerge. We do not doubt that our process allows this green chemistry to now be scalable, competitive, and even cheaper for several industries.

The most obvious application is in packaging — whether it is to replace PE coatings, get rid of PFAS or waxes, or to simply reduce pulp use while making corrugated board. Because the reaction is extremely fast, we believe it is possible to implement this at the papermaking stage to replace sizing agents like AKD with a potentially cheaper solution. We discover new applications regularly and see a new world of possibilities opening up.

The critical point to understand when developing applications and bioproducts is that chromatogeny is a covalent linkage grafting process using reagents derived from naturally occurring long chain fatty acids. Because of the covalent linkage, the end products from chromatogeny are “monomaterials” or monocomponent products. Multicomponent products — which associate, for example, layers of naturally occurring cellulose-based material such as paper sheets together with layers of synthetic polymeric material — are easy to prepare and efficient from a barrier point of view, but they are extremely difficult to process after use. To make a comparison, it is quite easy to dissolve salt into water, but it is extremely difficult to remove salt from water.

The big pluses of chromatogeny are first, that the end products are harmless biomaterials; second, because the long chain fatty acids are covalently grafted, the amounts needed to provide barrier properties are considerably lower than what would have been necessary through a conventional coating approach. In a nutshell, multicomponent materials may be viewed as “dumb and clumsy” while grafted monocomponents may be viewed as “smart and nimble.”

LOOKING TO THE FUTURE

In the opinion of the authors, the packaging industry (as well as pulp and paper) is going to see a paradigm shift. Packaging used to be considered a “low-tech” industry mostly concerned about mixing existing products without any considerations about their afteruse compatibility. The packaging of tomorrow will be much more sophisticated and will make use of the creativity of organic synthetic chemistry to design products that respond to specific packaging challenges and, notably, their life cycles.

A new concept needs to be implemented. Instead of the old “one process fits all” approach, we will see the development of the “fair” package concept, where different technologies will cohabit with design innovations. What is most exciting is that packaging will stop being an industry that mostly made use of results obtained in other disciplines — and will move to the forefront of research in sustainability. Other industries will very likely turn to the achievements of the packaging industry to provide solutions to their own sustainability challenges.

At this stage, Cellulotech is developing its industrial pilot and working with several companies on different projects. The company has a collaborative approach (see sidebar on page 16 about the development’s history) and we recognize we can’t do everything on our own with such a promising technology.

While the process won’t be commercially available in the very short term, Cellulotech invites any company interested to get in touch to better understand this technology and potentially work together on a specific challenge or application. The idea is that, once it is commercially ready (ideally, within the next two years), adoption can be smooth and quick.

Videos

Chromatogeny and paper towels: the lotus leaf effect

Making corrugated cardboard completely water resistant

History and Development

In the 1920s, scientists discovered that fatty acid chlorides could react with paper to make it superhydrophobic. However, the reaction was extremely slow and required a solvent, so it was not really of interest to the industry — it was more of a chemical curiosity. Then, on Christmas Eve in 1996, French chemist Daniel Samain made a chance discovery: this reaction could actually be made solvent-free and very fast. He named it chromatogeny.

Samain first worked in France within his own company and an industrial and public research institution to further study this process and its properties. They found that it could also be applied on PVOH coated paper, offering performances close to PE coated paper while remaining repulpable and compostable.

A pilot was developed more than 12 years ago. While it demonstrated the potential of the technology, the paper engineering approach used was unfortunately suboptimal and prevented scalability. Moreover, there was little interest at that time from the industry to find alternatives to its well-established processes.

In early 2019, investment professional Roman Metivet was working as the CIO of a family office on sustainability issues, notably packaging. While researching monomaterials he came across chromatogeny and was surprised it had not gained more traction. “When it was discovered more than 25 years earlier, there was limited interest simply because our knowledge of environmental issues was limited and there was no real reason to look for alternatives,” says Metivet. “Today, chemicals that we know to be harmful for humans and the environment are clearly being pushed toward the exit. The increasing demand for renewable and recyclable cellulose-based materials clearly provides a strong tailwind for chromatogeny.”

Eventually, Metivet traveled to France to meet Samain. After discussing the chemistry and other technical aspects, Metivet proposed that they create a new company to fund more research. This new company is Cellulotech.

“In some ways, the pandemic was a huge boost in our productivity, since we found a new application: producing 100 percent paper-based face masks,” Metivet says. “Lab trials also fueled creativity around the process, which has been considerably improved. We believe it is now scalable for the paper and packaging industries.”

Cellulotech is now developing its own industrial pilot and is working on joint research projects with different companies and universities.