From paper linerboard and tissue to aluminum foil and plastic films, FPInnovations’ Roll Testing Facility (RTF) can test any flexible web materials and can troubleshoot roll performance and web handling issues.

In 2002, FPInnovations opened the doors to its RTF in Montreal, Quebec to investigate and fix issues such as baggy edge and wrinkles that often the producers themselves were unable to identify the root causes. Almost 20 years and 4,000 rolls later, RTF’s goal remains the same: help producers improve product performance and efficiency in converting and printing operations.

In 2002, FPInnovations opened the doors to its RTF in Montreal, Quebec to investigate and fix issues such as baggy edge and wrinkles that often the producers themselves were unable to identify the root causes. Almost 20 years and 4,000 rolls later, RTF’s goal remains the same: help producers improve product performance and efficiency in converting and printing operations.

Analyzing web uniformity and roll structure

Web breaks, bagginess, wrinkles, and other roll structure defects can seriously hamper a producer’s efficiency, customer satisfaction, as well as the bottom line. Most of the time, these issues are related to poor web uniformity.

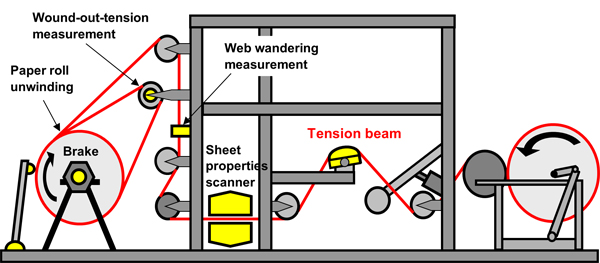

Through a complete analysis of web uniformity and roll structure, RTF can identify sources of web-related issues on the printing press and converting line. “RTF provides a unique set of profiles of key paper properties, such as tension, caliper, and moisture in order to troubleshoot complex and long-standing issues and determine the root cause of the problem,” explains Frédéric Parent, P. Eng., Senior Scientist, Paper Products Innovation group. Pinpointing problematic areas and providing recommendations for corrective actions help mills address complaints and costly claims from end-users.

Customers can also have good rolls compared against problematic ones through a benchmarking service that aims to pinpoint the differences between the two to solve the problems at hand. The outcome and deliverable of any RTF analysis include a full report with supporting data, an interpretation of the results, and recommendations for corrective actions.

RTF successes

The only facility of its kind in North America, RTF has serviced mills from Canada, the U.S., Asia, and Europe.

“Regardless of who the customer is, it comes down to three essential ingredients for producers: a high-quality product, minimum rejects, and a uniform web, all of which RTF can help achieve,” explains Frederic Parent. “Depending on the issue, the savings realized from improved efficiency can be in the order of millions of dollars per year for a typical paper machine.” Roll upon roll, RTF has improved mills’ bottom lines through enhanced efficiency, fewer web breaks, and increased sales.

Success stories:

- Improving Paper Machine Efficiency: Ridges and non-uniform profiles resulted in a mill having to reject the first 20 inches of paper at the front edge of the paper machine. With RTF analysis, FPInnovations was able to help the mill link the issues to specific paper machine unit operations such as press loading and drying uniformity. Implementing RTF’s recommendations improved paper machine efficiency by seven per cent, translating into millions of dollars saved annually.

- Increasing sales and competitiveness: One mill had a long-standing issue with baggy edges, causing wrinkles, rejects and end user claims. RTF’s recommendations enabled the mill to solve this issue by correcting the CD tension profile with dryer surface resurfacing, facilitating the production of high-quality, lighter-grade products. This opened the mill up to additional markets that were previously inaccessible. The result: a significant increase of millions of dollars in annual sales.

- Cutting paper breaks: Crepe wrinkles and a burst issue caused several web breaks per day on printing presses at another mill. RTF analysis revealed the issue was related to the use of a non-appropriate winding curve. This correction reduced the number of paper breaks by four per day and saved the mill more than $1 million per year.

FPInnovations’ world-class expertise and unique facilities such as RTF and other instrumentation and testing equipment are all a part of the equation that make it possible for paper producers as well as producers of other flexible materials to remain profitable in a highly competitive, global industry.

For more information about FPInnovations’ Roll Testing Facility, please contact Frédéric Parent, Senior Scientist, Paper Products Innovation group at FPInnovations

Source: FPInnovations