The push for decarbonization is now being felt from all directions, and as a result, your ESG performance can significantly influence your competitive standing.

It's not just consumer demand for environmentally-conscious companies that is on the rise, but government incentives and mandates are also becoming more prevalent.

As a result, companies in all sectors are integrating decarbonization into their strategies. An example of this is Southwest Airlines announcing a reduction of carbon emissions intensity by 50% by 2035 and aiming to rely on sustainable aviation fuel for 10% of their total jet fuel consumption by 2030.

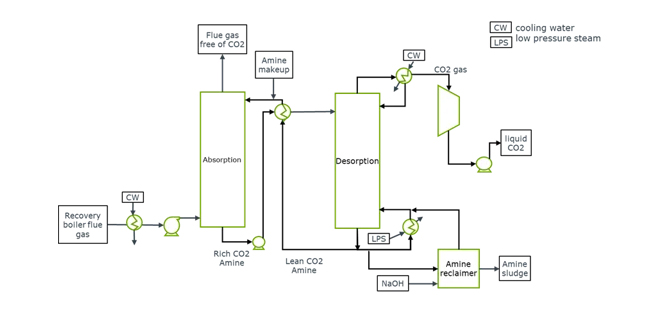

Due to its significant emissions, pulp and paper mills are now exploring carbon capture technologies. Below is an illustration of a typical commercial process for carbon capture using amine as a solvent.

US Pulp Mills' Role in Carbon Capture

US pulp mills are poised to gain a considerable competitive edge in biogenic carbon capture due to factors such as the Inflation Reduction Act, which offers substantial incentives specifically tailored for carbon capture and utilization within the pulp mill industry.

This includes refundable, transferable, and advanced direct pay tax credits through the 45-Q program. Additionally, during the ABLC Next conference held in October 2023, it was announced that an industrial facility would receive five years of interest-free direct pay credits, totaling $63 million. This significant support further enhances the competitive edge of US pulp mills in the realm of biogenic carbon capture.

Even the Department of Energy recognizes pulp mills as one of the best sources for biogenic carbon capture among heavy industries with expected revenue ranges in the highest of industrial capture.

For Further Insights, Read Our Blog Post "Are Pulp and Paper Companies Sitting on a Hidden Goldmine"

In fact, this year it was announced that the US Department of Energy selected International Paper’s Vicksburg containerboard mill for a feasibility study that could result in up to $88 million in grant funding for the construction of a carbon capture pilot facility. The carbon capture pilot will be a collaboration between RTI International, International Paper, SLB, and Amazon to build a carbon capture system at the mill.

In addition to such initiatives, there is potential for companies to differentiate themselves by searching for alternatives to reduce Scope 1 and 2 carbon emissions. Many are looking toward energy efficiency improvement projects by adapting to renewable fuel sources or modifying their production process to minimize losses.

FisherSolve's Benchmark Carbon Module has the estimated emissions for every pulp and paper mill in the world, which can help in selecting the most promising locations for carbon capture or carbon reduction projects.

Considering the current landscape, it is evident that a company's carbon footprint could play a crucial role in determining a mill's viability. As an example, we could use Benchmark Carbon data for International Paper’s Orange mill in Texas, which recently shut down.

When FisherSolve is used to examine its GHG emissions compared to other kraftliner mills in North America, we saw that the Orange mill, along with other recently shuttered mills, fell on the upper end of the carbon benchmark. This suggests that a company’s environmental impact can influence its viability.

For Further Insights, Read Our Blog Post “Is Your Carbon Position Impacting Your Mill’s Viability?”

Carbon Capture and Utilization to Methanol: A Pathway to Monetization

One exciting possibility for utilizing the carbon captured in a pulp and paper facility is the co-location of a methanol production facility. By utilizing the captured carbon and green hydrogen as raw materials, this process can produce green e-methanol, a renewable alternative to current fossil fuel production methods that rely on natural gas and coal.

With a worldwide production of more than 95 million mt/year, methanol is currently used as a raw material for other chemical production. It is even being considered as a replacement for marine fuel.

It's important to note that electrolysis of water to produce green hydrogen is an energy-intensive process, which demands the use of renewable power purchase agreements (PPAs) to ensure sustainability. The resulting oxygen of the process, known as "wet oxygen," would require drying before it can be sold commercially. However, it also has potential applications in bleaching and wastewater treatment processes within the pulp and paper plant.

This approach to methanol production holds promise for the future of low-carbon economies. The use of renewable methanol could lead to the creation of a wide range of chemicals. The development of methanol plants driven by fuel demand, with surplus products utilized in various chemical intermediates, mirrors the trajectory of petrochemicals in the past.

As US pulp mills consider their role in the low-carbon economy, they must address several key questions. These include:

- Is it best to pursue CCS (carbon capture and storage), CCU (carbon capture and utilization), or both?

- What process or technology should they invest in?

- What are the costs and paybacks?

- Are there opportunities for strategic partnerships?

- What is the value of CO2 feedstock? How can they adjust to CO2 prices?

Accessing the Right Resources to Make Profitable Decisions

By leveraging resources like ResourceWise's FisherSolve database and PRIMA CarbonZero platform, pulp mills can access valuable information, insights, and data on the viability, costs, energy consumption, and carbon footprint of their operations. This knowledge will enable them to make informed decisions and navigate the evolving landscape of decarbonization successfully.

ResourceWise goes beyond providing top-notch data by offering exceptional consulting services tailored to your company's needs. Our team of experts, with their extensive experience and expertise, will provide you with comprehensive answers and valuable guidance on all your decarbonization and carbon capture inquiries. With our research projects, you can stay ahead in the ever-evolving landscape of sustainability to make informed, profitable decisions.

Learn More on Strategic Consulting

Source: ResourceWise