EPIQ AD, has redefined industry standards through its innovative equipment solutions from pulper feed systems to roll finishing.

Most EPIQ AD equipment are found on the periphery of the paper machine from the pulp preparation zone, the first exit deck and finally to the warehouse with AGV/AMR integrated solutions.

Rooted in the philosophy that higher production demands fewer operators, EPIQ AD's approach represents a shift in manufacturing efficiency.

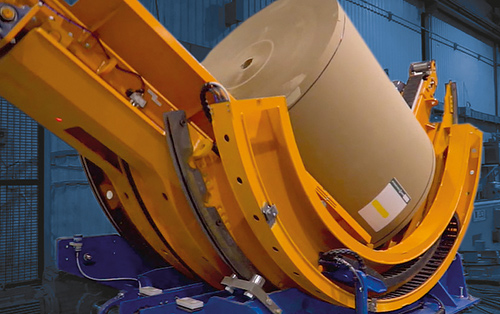

Their robotic dewiring system offers unparalleled results. As for the Roll finishing system, it ensures that the rolls are handled with careful care to prevent damages. It wraps, caps, labels, crimps, straps and shrink wraps like no other Roll finishing system.

Yet, EPIQ AD are steadfast partners dedicated to enhancing productivity within the paper mill. Their team comprises highly skilled engineers, designers, and project managers, all poised to optimize your plant within your specified timeline and budget constraints.

With a legacy spanning five decades of successful business ventures, EPIQ AD stands as a beacon of reliability and innovation. Their pride lies in tailoring new equipment and comprehensive material handling solutions to meet the unique requirements of your pulp and paper mill.

EPIQ AD is a product line of EPIQ Machinery. They engineer global solutions of innovative equipment to improve the handling and process flows of aluminum smelters, pulp and paper mills and hydrometallurgy. EPIQ Machinery blurs the lines between being a technology company and a heavy machinery manufacturer, by continuously integrating new technologies into its equipment.

Source: EPIQ Machinery