ANDRITZ helps you boost production

In BCTMP line, two wash presses that had reached their performance limits represented a bottleneck. Initially, only one of the screw presses was upgraded. And the results were so convincing that the same measures were implemented in screw press 2 one year later. With benchmark results …

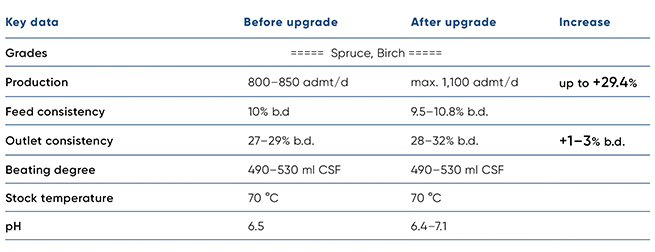

A European pulp mill was upgrading process areas of their BCTMP line step by step to eliminate bottlenecks that were affecting plant availability. The challenge with two ANDRITZ wash presses was casual fluctuations in flow at high throughputs, pushing the screw presses to their performance limits. The customer's target was to increase production to at least 1,000 admt/d at each press compared to the current throughput of 800–850 admt/d – a minimum increase of 17–20%. Outlet consistency after the upgrade should not fall below 24% if it cannot be maintained at the same level as before. Speed range – and thus energy consumption – was also to remain unchanged.

Upgrade scope

First of all, only one ANDRITZ SCP1410 was upgraded, with the following scope:

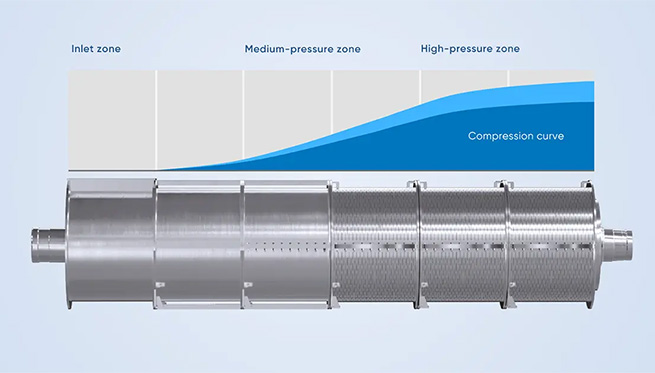

- Installation of a new Low-Energy Screw Shaft (LESS), enabling a new compression curve for higher throughput at the same installed power

- Split, grooved baskets for the medium-pressure zone to widen the operating window of the press and allow higher production rates

- Coated body plates and screw flight with full wear protection

One year later, the same measures were implemented in screw press 2.

A new screw with customized compression curve is the key to higher production.

A new screw with customized compression curve is the key to higher production.

Benchmark results

Benchmark results

- Capacity boost by close to 30%

- Slightly improved outlet consistency

- Same speed range

- Adapting better to flow fluctuations

- More stable operation

Results in detail

Average values from two presses

Source: Andritz