Hybrid structured tissue is a term that has risen to describe the latest iterations of structured tissue machines which forego the through air dried sections of the dominant structured platform approach.

There are many reasons why a tissue maker would want to create a structured base sheet without having to dry it via evaporation as with a TAD (Through Air Dryer). The two most obvious are the inherent energy inefficiency of evaporative drying and the cap on production imposed on the machine due to this inefficiency. This is particularly problematic at this time in Europe with the tissue industry heavily reliant on natural gas for hood operation.

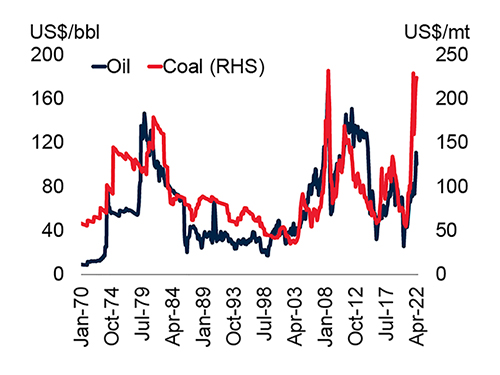

Figure 1: Real natural gas prices from World Bank.

Figure 1: Real natural gas prices from World Bank.

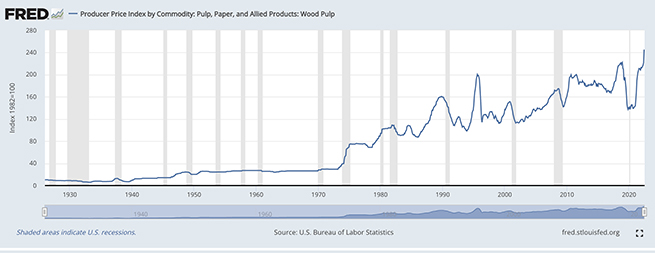

An advantage that hybrid structured technology brings versus the conventional tissue production is increased bulk to basis weight. This allows creation of high quality base sheets at lower basis weights which is particularly advantageous given the rising cost of pulp.

Figure 2: Producer Price Index for Wood Pulp. Source: U.S. Bureau of Labor Statistics as shown on www.fred.stlouisfed.org.

Figure 2: Producer Price Index for Wood Pulp. Source: U.S. Bureau of Labor Statistics as shown on www.fred.stlouisfed.org.

A hybrid structured machine uses more efficient dewatering processes including vacuum, belt pressing and shoe presses combined with methodologies that protect the sheet structure during the dewatering. The resultant sheet being transferred to the Yankee contains a significantly higher moisture level when compared to the TAD process and is much closer to conventional tissue making. With this method, the Yankee and hood sections’ capacities are utilized much more compared to many TAD machines, which in some cases are installed with no hoods at all. Being able to do this, while still generating the desired sheet structure and absorbency capacity increases, provides a significant potential for cost savings and profit opportunities generated by the new platforms.

Several approaches to the hybrid structured platform have been launched by various OEMs (Original Equipment Manufacturers) as well some proprietary technology approaches developed by tissue companies. NTT and QRT by Valmet, ATMOS by Voith and eTAD by Georgia Pacific are possibly the most well-known iterations of hybrid structured technologies. Each of these has faced their own challenges in producing quality tissue/towel at high speed, and they all tend to share two common challenges:

- Intimate transfer of the web

- Temperature intolerance of the prevailing Yankee coating chemistry

The solution for both the OEM and chemistry provider is to find a chemistry that can manage the moisture levels and inherent variability at the nip with hybrid structured machines. In so doing, uniform attachment results in uniform creping energy across the sheet. Failing to achieve this, the rolls produced will suffer from highly variable reel build across the roll width.

Poor reel build is not just an aesthetic issue for the production floor. The variability observed is telegraphing the bulk to basis weight and quality variation of the base sheet itself in these areas. This variability tends to create much difficulty on the converting lines, resulting in lower line speeds at best and high cull numbers at worst.

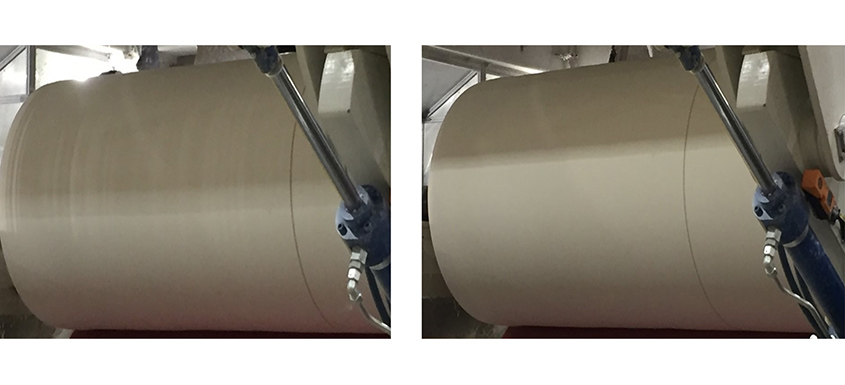

Figure 3: Example of corrugation and poor reel build often experienced in hybrid structured tissue.

Figure 3: Example of corrugation and poor reel build often experienced in hybrid structured tissue.

Intimate and uniform transfer of the sheet from the structured fabric to the Yankee is the foundation for high speed production and a value added creping process. Taking advantage of the optimized sheet transfer to the Yankee means speeding up, and higher speeds mean higher Yankee surface temperatures. The higher temperatures harden the prevailing Yankee coating packages which are PVOH(Polyvinyl Alcohol)-heavy in their make-up. This can then shrink the operating window, particularly for higher PVOH-based Yankee coating packages if not correctly modified by the other supporting Yankee coating components. Minimizing the use of PVOH and its correct modification allow for a more temperature tolerant and doctorable coating film leading to fewer blade changes, reduced risk of chatter and more consistent quality and performance.

To address these issues suppliers have developed an array of adhesive technology that provides hybrid structured manufacturers with coating packages that can deliver the needed performance for these challenging nip transfer conditions. These new approaches minimize the use of PVOH while keeping the complexity of the system down via fewer individual components for the operators to manage.

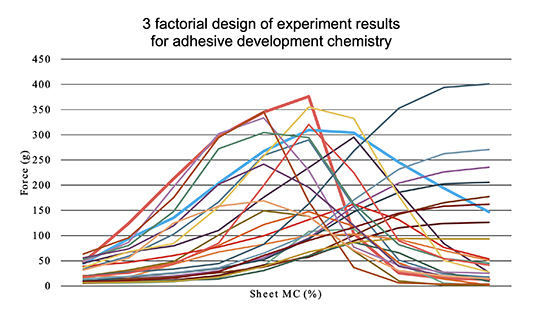

Figure 4: Depiction of how changes in adhesive molecular structure impacts adhesion development vs moisture content.

Figure 4: Depiction of how changes in adhesive molecular structure impacts adhesion development vs moisture content.

Given that different machine configurations, basis weights, furnishes, etc. result in almost unlimited variation in transfer conditions, correctly matching the chemistry to the right machine requires an analytical approach. This requires an expert audit of the process by the coating supplier so that the constraints of the given process can be contrasted against the available chemistry options. The manufacturer then can understand how the properties of the new chemistry will lend itself to helping achieve the operations and quality objectives.

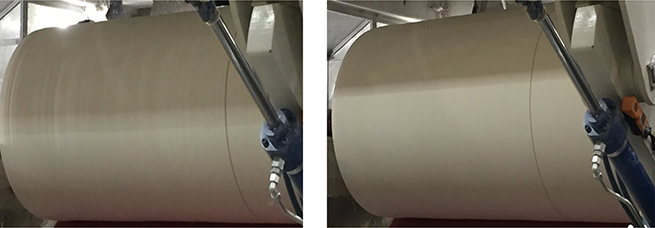

Figure 5: Improvement in hybrid structured reel build with selection of a suitable coating chemistry (before on left and after on right).

Figure 5: Improvement in hybrid structured reel build with selection of a suitable coating chemistry (before on left and after on right).

The possibilities for improvements as shown in the pictures above will result in economic returns thanks to more efficient drying and higher quality tissue. The benefits are measured in millions of dollars for the operation.

About the Authors

Mark Christopher is Global Market Manager at Buckman

Paul Howard is Global Industry Specialist at Buckman

About Buckman

Buckman is a privately held, global specialty chemical company with headquarters in Memphis, Tennessee, USA. Buckman works proactively and collaboratively with our worldwide customers in pulp and paper, leather, and water treatment to deliver exceptional service and innovative specialty chemical solutions to help boost productivity, reduce risk, improve product quality, and provide a measurable return on investment. Buckman is committed to safeguarding the environment, maintaining safety in the workplace, and promoting sustainable development, for our more than 1,500 associates, our customers and our communities in more than 90 countries around the world. www.buckman.com