The ABB Ability™ Performance Service provides auto-correlating calculations for online conditioned weight measurement to enable mills to reduce quality losses by getting on-spec faster during sheet breaks and start up events.

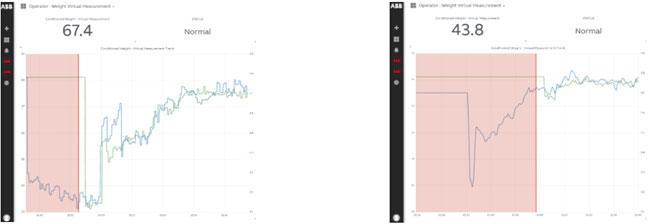

Dashboard comparison showing results of using (right image) or not using (left image) Weight Virtual Measurement. The right image shows the properties are able to meet specifications faster after a sheet break.

Dashboard comparison showing results of using (right image) or not using (left image) Weight Virtual Measurement. The right image shows the properties are able to meet specifications faster after a sheet break.

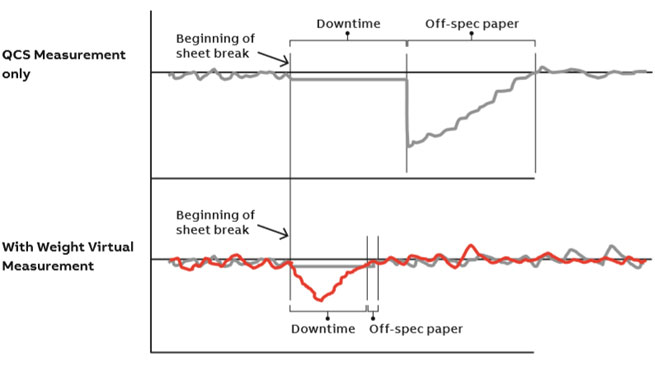

If the QCS is offline for maintenance or during a sheet break, operators are blind to the moving web’s weight measurement.

ABB Weight Virtual Measurement helps operators get (and maintain) weight properties within their target limits while the paper machine is starting up—reducing sheet break recovery times in the process.

By using machine learning-generated models to provide accurate, online measurements (also known as soft sensors), you can increase production throughput and reduce quality losses.

ABB's approach to soft sensors

Our new approach to soft sensors combines unrivaled proficiency in advanced analytics, an online calculation engine with auto correlation and ongoing performance analysis for unparalleled accuracy and integration opportunities.

Delivery through ABB Ability™ Collaborative Operations for pulp & paper enables ABB experts to provide machine-specific analysis with periodic performance checks and model updates. Data is viewed through a web-based user interface that is easily accessible by customer or ABB personnel.

How it works

First, an initial static conditioned weight model is created using historical machine data to establish an initial expectation of the accuracy of the calculated conditioned weight.

Once the accuracy of an initial model is confirmed, an online calculated weight measurement is implemented by leveraging the ABB Ability™ platform.

The third step is on-going performance monitoring and optimization tasks to maintain and improve the conditioned weight calculation by compensating for any machine changes or implementing on-going solution improvement updates.

Grey line = QCS measurement; Red line = Online weight calculation

Grey line = QCS measurement; Red line = Online weight calculation

Source: ABB