My name is Rick Lull and I am a Senior Applications Engineer at Kadant Johnson. I have a degree in Paper Process Engineering and have worked as a Kadant Johnson applications engineer for 20 years.

My role is to recommend product solutions based on the application. I am also here to answer the technical questions that others cannot. In all of this, the most common question I receive is “How much torque is required to mount rotary pressure joints?” The answer is simple but first let me give you some background.

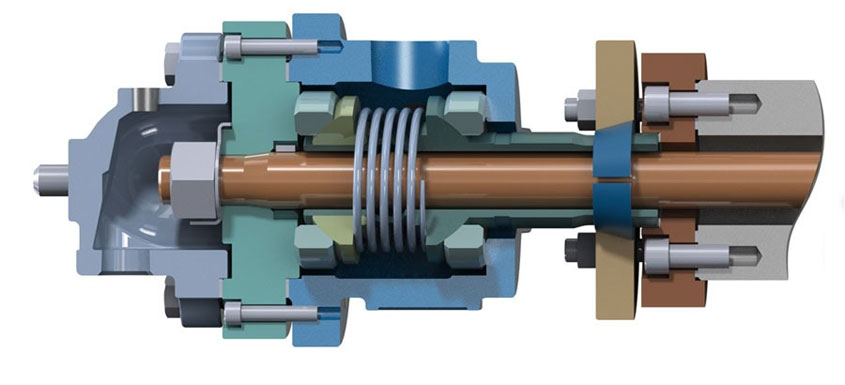

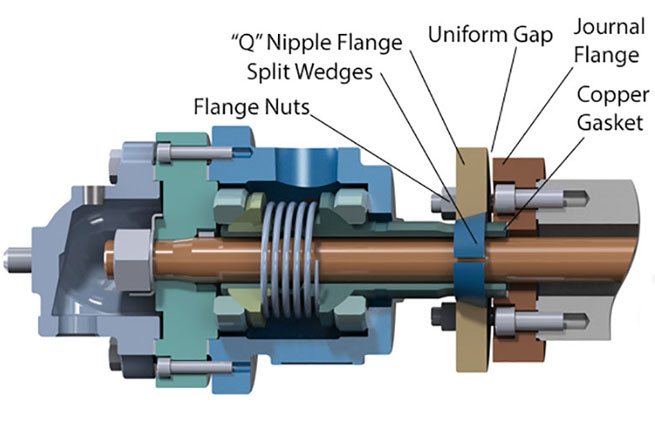

Rotary pressure joints, those joints that increase sealing force with increased pressure, are commonly attached to the journals of rotating equipment using a quick connect “Q” nipple flange. This allows the rotary joint to be removed quickly from the journal and the internal components of the rotary joint to be serviced. When customers ask, “How much torque is required to mount rotary pressure joints?” they are specifically enquiring about the torque specification to tighten the flange nuts attaching the “Q” nipple flange to the journal flange. The first part of my answer is that there is no torque specification.

There is no torque specification because nipple and journal flange bolt patterns vary greatly, which have a huge impact on torque requirements. Also, the “Q” nipple flange can be made of cast iron, steel, a casting, or a piece of bar stock. These different materials impact the bending of the flange and hence the torque required.

The second part of my answer on “How much torque is required to mount rotary pressure joints?” is to measure the separation between the “Q” nipple flange and the journal flange. The flange nuts should be tightened until there is a 1/8” to 3/16” gap (3 to 5 mm) between the flanges. The gap should be uniform around the entire circumference of the flanges. The proper spacing ensures the split wedges and the copper gasket are properly loaded to seal the nipple to the journal and a uniform gap ensures the rotary joint is properly aligned.

Source: Kadant