Vacuum systems are essential for papermaking as they contribute to dewatering, sheet properties, overall press performance, felt conditioning, and general machine efficiency.

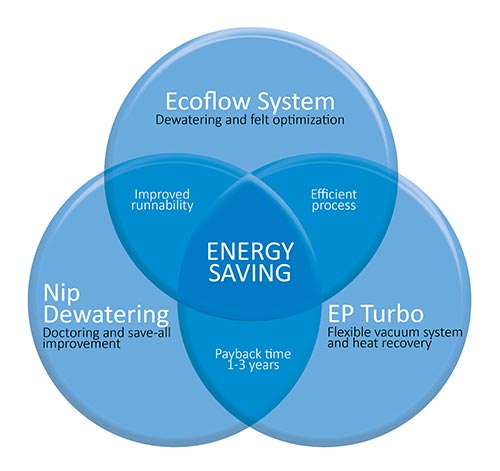

Fit-for-purpose vacuum system and efficient doctoring and save-all solutions for forming and press sections are the fundamental base for the good energy efficiency and low cost paper production. Understanding the dewatering process is the key to a well-working vacuum system.

Vacuum at a paper machine

Vacuum at a paper machine is used for a variety of reasons. Dewatering the paper sheet is the obvious one. Holding and controlling the route the sheet takes through the press section and conditioning the press felts are other key uses of vacuum in a paper machine. Vacuum is also used to hold and control the water removal from suction roll holes.

Early paper machine designs did not use vacuum at all, but relied on gravity and press nips to dewater paper. Machine speeds were then much slower than what we are accustomed to today. Nowadays, it is difficult to imagine a paper machine without a vacuum system and uhle box dewatering being today still the most common way to dewater the paper in a press section.

The vacuum levels at a paper machine are typically between 5 and 70 kPa, which is relatively low compared to other vacuum applications, for instance, in the chemical industry. The air flows, though, are very high due to the large open areas of various vacuum elements we see in a paper machine.

Vacuum, which is a result of air being pulled through a restriction, is an expensive tool; it is one of the top three energy consumers in a paper mill. Historically it has been made available in abundance, and often used in excess. Today we face increasing cost of energy. Paper mills are demanding reduced operational costs to stay competitive. Therefore, it makes sense to review air flow demands and, when suitable, apply old school thinking, i.e. nip-dewatering rather than uhle box dewatering.

Ecoflow™ dewatering measurement system

The primary function of wire and press section in a paper machine is to remove water from the paper sheet. In order to understand the effectiveness of individual elements (such as save-all pans and suction boxes) dewatering rate must be measured. Without this, the critical review of the needed air flow (i.e. vacuum level) and consequent optimization cannot be successfully carried out. Water that is removed from the paper sheet contains air, and is often subject to foaming. Traditional magnetic liquid flow meters demand a homogenous flow and will not be able to provide accurate data. Ecoflow™ meters are designed to measure water flow across a mechanical restriction and are not sensitive to entrained air or foaming. These devices are used both under vacuum (in a separator drop leg) and in atmospheric conditions.

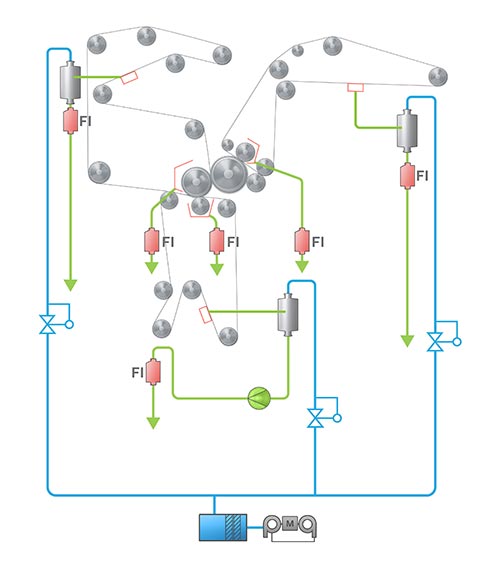

Picture 2 – Fit-for-purpose vacuum system and efficient doctoring and dewatering solutions for forming and drying sections are the fundamental base for the good energy efficiency and low cost paper production.

Picture 2 – Fit-for-purpose vacuum system and efficient doctoring and dewatering solutions for forming and drying sections are the fundamental base for the good energy efficiency and low cost paper production.

Understanding dewatering effect developed vacuum system further

Understanding the dewatering more deeply resulted in realization that the vacuum system should be flexible. Paper machine conditions change all the time. For example, machine speed can easily vary from 500 to 1,100 m/min depending on basis weight and furnish. Felt condition will change over its lifetime and it’s not optimal to have the same amount of vacuum (-kPa and/or air flow) for different conditions. 30 years of experience tells it’s very important to be able to measure water removal and control the vacuum levels. Traditional vacuum technologies are not good if the target is to optimize vacuum levels, minimize power consumption and adapt to the changing conditions.

Runtech’s target is to make a dry vacuum system with variable capacity (air flow) and then give a possibility for the machine operator to select vacuum levels based on the actual need. What defines the need? In case of flat boxes and Uhle boxes it’s most probably the water removal based on Ecoflows. In case of Pick-Up and transfer rolls it’s typically runnability and in case of press suction rolls it can be both runnability and dewatering. In many cases a slightly higher vacuum for the PU rolls is required during sheet pick-up, but after that the vacuum level can be normally reduced. This will potentially give a high energy saving and can be easily put in to the start-up logic as well. When facing any runnability challenges, such as edge flipping or dropping at the end of a felt life time e.g. in the PU felt loop, the PU roll vacuum can be easily ramped up with the speed controlled turbo. Naturally, same applies to press suction rolls as well. Typically, machine suppliers specify -65 kPa vacuums for press suction rolls, but in many cases, such high vacuum is not needed. For machines running less than 1000 m/min, -40…-50 kPa is a sufficient level depending on the sheet properties. This difference is easily 100,000 EUR/year. Online dewatering measurement system is an easy way to find the correct vacuum level.

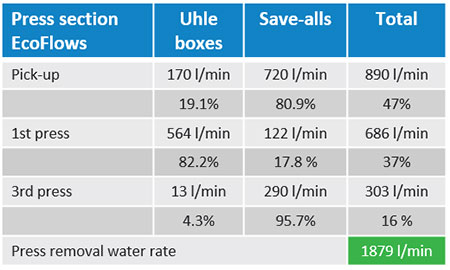

Picture 3. Typical press section Ecoflow system for 3-nip paper machine. Based on the data it’s very easy to compare different felts and adjust water removal.

Picture 3. Typical press section Ecoflow system for 3-nip paper machine. Based on the data it’s very easy to compare different felts and adjust water removal.

Increased dryness with optimized doctoring

The most economical method of water removal in a press section is nip dewatering, as opposed to uhle box dewatering requiring higher air flow and thus higher energy consumption. Nip dewatering is facilitated by allowing felts to run with high enough moisture level to increase the hydraulic pressure in the press nip. The water pressed in the roll surface open area needs to be then, in turn collected with suitable doctoring and save-all equipment. Suction rolls are often equipped with double doctors to prevent re-wetting and maximize void volume to allow best water removal. Save-all pans should be designed to manage the water that is removed from the nips, and engineered to be rigid enough to accommodate doctor holders.

Dewatering and doctoring are not only related to energy consumption, but also play a big role in paper machine runnability, efficiency and profitability, as well as paper profiles. Therefore, a well-designed and operated dewatering and doctoring system is the key to a well-performing and energy-efficient press section.

Press section dewatering and doctoring is a big part of Runtech’s energy saving solution. Water is removed in two places: Nips and Uhle boxes. If press roll doctoring is not perfect, Uhle boxes are needed. Runtech aims to build doctoring so that with correct type of felts customers can reduce the uhle box vacuum to minimum or even fully close the Uhle boxes. Runtech’s doctoring and save-all system, together with EcoFlows actually allows the customer to see the potential in the nip dewatering strategy.

Especially for slow machines (< 600 m/min) it is critical to design the doctoring correctly because roll centrifugal force and water kinetic energy are low. Fast running machines are easier because water flies out from the press rolls automatically due the centrifugal force. Several of Runtech’s customers are now running without Uhle boxes or reduced vacuum levels, even though machine speeds with heavy basis weights can be < 300 m/min.

Runtech is one of the leading suppliers for the improved dewatering and doctoring solutions for the all kinds of pulp, paper, board and tissue machines. In many cases, Runtech’s solutions lead to a 1-3% increase in dryness after press section which saves considerable amount of energy in the dryer section (4-12% less steam).

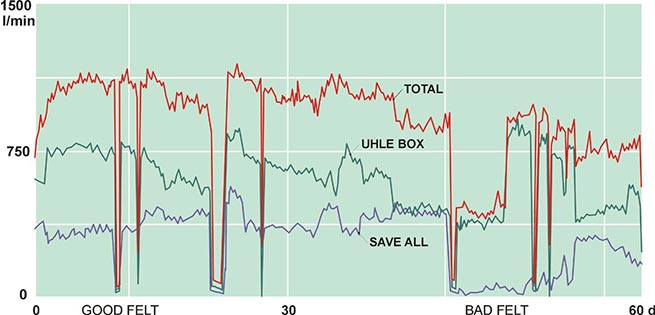

Picture 4. Classic example from Uhle box vacuum level optimization. It’s important to measure both nip and Uhle box because otherwise full picture is not seen. Uhle box vacuum level was optimized from the -40 to -28 kPa. Uhle box dewatering goes down but at the same time felt is more saturated so it starts to work better in the nip and nip/ total dewatering increases. In these running conditions, maximum water removal was reached with -28 kPa Uhle box vacuum.

Picture 4. Classic example from Uhle box vacuum level optimization. It’s important to measure both nip and Uhle box because otherwise full picture is not seen. Uhle box vacuum level was optimized from the -40 to -28 kPa. Uhle box dewatering goes down but at the same time felt is more saturated so it starts to work better in the nip and nip/ total dewatering increases. In these running conditions, maximum water removal was reached with -28 kPa Uhle box vacuum.

30 to 70% energy savings with Ecopump Turbo blowers

Vacuum is created as a result of moving air across a restriction. Fans, turbo blowers and liquid ring pumps can be used to achieve this. Often paper mills use a combination of these.

Turbo blowers have the benefit of being an inherently efficient way of compressing air for the modest compression ratios (less than 3.5) we face at a paper machine. A turbo blower is, for a given rotational speed and impeller design, a constant compression ratio device as opposed to a liquid ring pump which is a constant displacement machine. The power consumption of a turbo blower is a function of the air flow that is being compressed to satisfy the pre-determined compression ratio.

Each vacuum element in the machine, such as suction box or suction roll, need a certain amount of air flow to operate at an ideal vacuum level. The needed capacity is depending on felt life and type, paper grade, basis weight, machine speed etc. Traditional liquid ring pumps and fixed speed blowers cannot cater for these dynamic vacuum and flow needs, resulting in, often significant, waste of energy. A liquid ring pump system needs bleed air valves to control the vacuum at paper machine element, while taking the same amount of power regardless of the situation and actual need at the machine. A fixed speed turbo blower system will have a lower total efficiency since typically large number of vacuum elements with various vacuum levels are connected together and all vacuum adjustments require throttling leading to high expansion losses.

RunEco EP Turbo Blowers are designed to operate efficiently across a wide range of vacuum levels and air flows to allow paper mills to optimize vacuum levels while taking advantage of the higher efficiency a blower has over a traditional liquid ring pump device. High speed motors driven by frequency converters allows a typical RunEco blower to provide paper machine vacuum levels between 30 and 70 kPa. Wide range of impeller designs allow high efficiency levels across the operating range. This means that the amount and the usage of throttling valves can be reduced to a very minimum. The result is 30 to 70% energy savings compared with traditional vacuum systems.

EP Turbo Blowers are always variable speed and capacity units. A built-in integrated high speed motor makes the system very compact and easy to install. In most of the cases, Runtech can replace the existing system with minimum piping and civil work costs. Big part of the installation is done during the normal machine run and only short shutdown is needed for the final tie-in valve connections. In normal rebuild cases energy saving is 40-60% compared to the old system. Furthermore, EP Turbo Blowers are a dry system i.e. they operate without any sealing liquid (water) thus contributing significantly to water savings in a paper mill while reducing the risk of any pathogen growth, such Legionella-bacteria, to a minimum.

Tailor-made RunEco solutions - no compromises

Depending on the paper machine design and width the most efficient operation sometimes requires one and sometimes several EP Turbo Blowers. The specified air flow capacity is typically quite high consisting of overall safety margin, felt life and type margin and with liquid ring pumps e.g. pump wear and seal water temperature variation margins. In normal operating conditions the needed air flow capacity is often ~30…50% lower than the specified capacity. Regardless of the situation, RunEco system with a fully speed-controlled turbo blower provides high operating efficiency at all times.

Vacuum system and dewatering audits

As we know, vacuum demand varies with different paper grades, felts and machine speeds, therefore a tailor-made solution with flexible and variable capacity can balance the supply and demand, resulting in both optimized dewatering and minimized power consumption. For those reasons Runtech is performing professional vacuum system and dewatering audits, prior to a rebuild project, for its customers.

Runtech engineers have done thousands of vacuum system audits and dewatering studies at paper mills over the last 20 years. Those studies and audits enables Runtech to benchmark the effectiveness of existing vacuum systems, dewatering equipment, suction elements, fabrics and felts. These pieces of information come together in a, often stepwise, rebuild and upgrade plan that will result in minimized operational expense coupled with production increase and/or runnability improvements.

Towards smaller carbon footprint

Runtech considers energy saving projects as bigger packages. It’s not only the vacuum pump or Turbo Blower in the basement. The target is to understand what happens on the machine level and what might be wrong or different on the paper machine. Combining Ecoflows, press section doctoring and heat recovery to the vacuum system rebuild project will most probably shorten the payback time significantly.

Many companies have committed to reduce their CO2 emissions before 2030. 1,5 MW saving in the vacuum system saves an average of 4,000 t CO2 a year. Vacuum system optimization projects are a very efficient way to reach these targets.

Customer results with EP Turbo Blowers

One very good example is DS Smith Kemsley PM6, where the existing vacuum system with constant speed turbo blowers was replaced by four Runtech Turbos and energy saving was 50%. Production Manager Stuart Ruck also highlighted that the new vacuum system allows them to start-up the felts in the optimal way and this has shortened the PU felt start-up period to 8 hours, which means extra production.

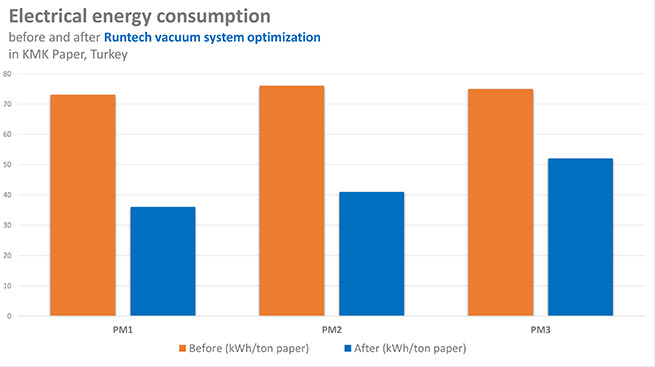

Kahramanmaraş Kağıt (KMK Paper) has three vacuum systems running, all supplied by Runtech. These installations have brought the mill significant savings not only in energy and water, but also by allowing a 4-5% increase in production. During the rebuilds, total of nineteen liquid ring pumps were replaced with three EP Turbo Blowers, each unit supplying one paper machine.

Picture 5. Electrical energy consumption before and after Runtech vacuum system optimization in KMK Paper, Turkey.

Picture 5. Electrical energy consumption before and after Runtech vacuum system optimization in KMK Paper, Turkey.

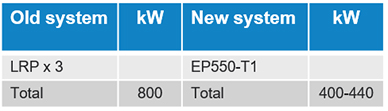

Lee&Man Tissue TM3 was a vacuum system rebuild project for a double width tissue machine in the Ruichang site in central China. In the existing system there were three liquid ring pumps consuming altogether ~800 kW. The new system was rebuilt with one EP550-T1 turbo unit replacing all the pumps.

After start-up the turbo operation was optimized with the help of EcoFlow dewatering equipment enabling a reduction of ~50% of the energy consumption during normal operation. All energy efficiency targets have been reached and sealing and cooling water consumption fully stopped.

Picture 6. Replacing liquid ring pumps resulted in 50% energy savings.

Picture 6. Replacing liquid ring pumps resulted in 50% energy savings.

Runtech Systems is a Finnish-based company that develops, designs and supplies equipment to the paper, tissue and pulp mills. Hundreds of paper, tissue, board and pulp mills benefit from our dewatering meters, vacuum systems, tail threading equipment and doctoring solutions. Years of hands-on paper-making know-how differentiates Runtech from traditional hardware suppliers. Our customers benefit from integrated solutions that result in significant operational cost savings, improved machine runnability and product quality. Today Runtech is a part of Ingersoll Rand.

Source : Runtech Systems