Flow variability can have a significant impact on processes and machinery health.

Supply pressure, back pressure and process pressure variations can all cause flow variations. Implementing Constant Flow Regulators (CFRs) can help maximize plant efficiency, save energy, and save money too.

Process stability and efficiency are the end goals. Flow indication and measurement with reliable flow meters is the first step. Adding a constant flow regulator to in-line flow meters can reliably stabilize flow in applications where supply or back pressure varies. CFRs are designed to provide a constant flow of liquids or gases, regardless of pressure variations.

How CFRs work

Variations in supply are often seen in low liquid flow applications where supply or back pressure varies and in gas flows where back pressure varies. A CFR will keep the pressure differential across a valve constant. When the pressure differential is kept constant, the flow will be constant.

“A CFR regulates flow by maintaining pressure differential.”

Flow regulation is achieved by attaching a membrane type differential pressure controller to a compact variable-area flow meter. For medium volume flows, CFRs with a built-in needle valve add a flow rate adjustment option. It should be noted that for very low flows, a minimal pressure differential is required to reach a point beyond which the CFR will function properly.

ESKO Model EFR3 Constant Flow Regulator mounted on Model ELF flow meter

ESKO Model EFR3 Constant Flow Regulator mounted on Model ELF flow meter

ESKO Model EFR14 Constant Flow Regulator pairs with ESKO EM Series medium flow meters

ESKO Model EFR14 Constant Flow Regulator pairs with ESKO EM Series medium flow meters

Typical CFR Applications

1. Bubble Tube Level Measurement

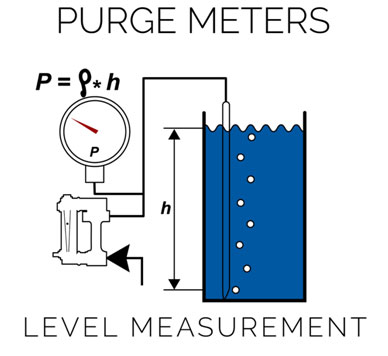

Tank level measurement is often achieved with bubble flow technology using purge flow meters as illustrated in Figure 1. A bubble tube (with air flow) is installed from the top of the tank, down to near the bottom of the bank. The hydrostatic pressure of the liquid in the tank essentially provides the measurement. To achieve measurement, it is therefore essential that the bubble tube remains full of air, not full of the liquid that is being measured.

Figure 1 - Tank level measurement using bubble tube.

Figure 1 - Tank level measurement using bubble tube.

In this application, tall tanks containing liquid need constant flow regulators to keep the bubble tube purged with a constant rate of air flow. The same principle applies when density is measured with bubble tubes in applications where total head varies significantly.

2. Bubble Tube Density Measurement

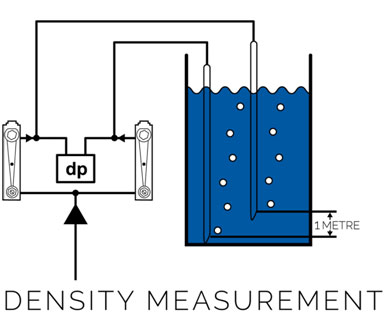

Density measurement of tank contents can be achieved by installing two bubble tubes as shown in Figure 2. If the tips of the tubes in the tank are a known distance apart, then the pressure differential between those two tube tips is proportional to the specific gravity of the liquid being measured. Again, in this type of measurement, the air purge rate is critical because if one tube is purging at a higher rate than the other, the pressure differential measured is not just a proportion of specific gravity but also supply pressure at the measuring point. A pressure differential CFR can be utilized to normalize the purge rates.

Figure 2 - Density measurement of tank contents using two bubble tubes

Figure 2 - Density measurement of tank contents using two bubble tubes

3. Pressurized Instrument Enclosures and Cable Pressurization

Instrument enclosures and cabinets may be pressurized to ensure that sensitive instruments are operating in a clean environment and to prevent corrosive gases or liquids from entering the enclosure. A steady flow of clean air into the enclosure can be maintained with a CFR.

Cable pressurization is used to reduce the possibility of standing water accumulating in enclosed cable conduits. A CFR can maintain a steady minimal air pressure to prevent water buildup and minimize corrosion or other damage.

4. Gland Water Applications/Batch Digesters

In pumps with large back pressure variations, seal water supply into a mechanical seal or stuffing box can vary. A stuffing box assembly is used to house a gland seal to prevent leakage of fluid between turning parts of machine elements.

A typical example is a batch digester. When cooking starts, a liquor circulation pump only has hydro-static pressure. Without a constant flow regulator, flow of water into the seal or stuffing box can be very high. As cooking continues and pressure builds, in addition to the hydro-static pressure, back pressure will increase, significantly reducing the flow. In this application, constant seal water into the pump seals is required to optimize water use.

5. Orifice Plate/Differential Pressure (DP) Cell Flow Measurement

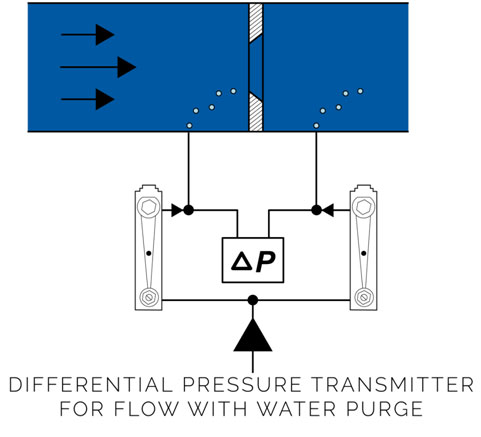

Orifice plates can be used to restrict or control flow of various process fluids. In this application example, Figure 3, constant water purge into the orifice plate connections is necessary for accuracy of flow measurement. Pressure can be affected by varying supply pressure or by clogging of the pressure connection. With manual adjustments, daily or even more frequent checks may be necessary to keep the purge flow constant. Utilizing CFRs automates control of purge flow.

Figure 3 - Flow measurement using orifice plate.

Figure 3 - Flow measurement using orifice plate.

Taking Control with CFRs - Question to Consider

“Could taking control of inflows or outflows stabilize the process?”

“Could stable flows help protect machinery?”

If the answer is yes, then CFRs have the potential to provide numerous benefits including:

- increased process uptime

- water savings

- minimizing waste water

- savings on maintenance and equipment costs

Where small to medium flow meters are already installed, a CFR may be an easy addition, but CFRs can also be installed without a flow meter/monitor.

The most common applications of flow meters paired with CFRs in pulp and paper processing include:

- seal water/cooling water

- tank level and density measurement

- orifice plate flow measurement

- solvent/additive inflows

- batching liquids

- moisture control

- air purging

Choosing the Right CFR

Sourcing well designed and constructed CFRs will prevent interruptions and protect equipment, even where large pressure differentials occur.

Choosing a solid and robust stainless steel CFR will provide longer life and reliability. ESKO CFRs are designed to be compatible with ESKO manufactured variable area flow meters of corresponding flow ranges. The body of the unit, the diaphragm and O-ring seal materials are designed to withstand harsh conditions and continuous use.

If you are considering the addition of CFRs to stabilize liquid or air flows, consult with the experts at ESKO Pacific Sales Ltd.

In addition to manufacturing a comprehensive line of variable area flow meters, oval gear meters and monitoring equipment, ESKO Pacific also manufactures compatible CFRs in two sizes:

1. For Low Flows/Purge Flows

Model EFR3 Constant Flow Regulators for Low Flows/Purge Flows

This durable compact unit (up to 3 liters/minute) pairs easily with ESKO manufactured Model ELF flow meters.

https://www.eskopacific.com/EFR3.php

2. For Medium Flows

Model EFR14 Constant Flow Regulators for Medium Flows

This robust heavy-duty unit provides automatic regulation (up to 20 liters/minute) and fits on ESKO manufactured Model EM flow meters. This unit is a membrane differential pressure controller with an integrated flow control valve.

https://www.eskopacific.com/EFR14.php

For more information about ESKO Pacific, visit www.eskopacific.com