Why teleoperation of harvesting machines?

A further stage in the evolution of harvesting is teleoperation, which would enable harvest machines to be operated remotely and out of the operator’s sight. This provides an opportunity to combine human attributes such as awareness, perception, and decision making, with the advantages of autonomous machine functions such as precision, accuracy, and task repetition.

Benefits and challenges

Teleoperation may improve machine productivity and consequently, reduce harvesting costs. This could be realized by having one operator operating two machines simultaneously, safely, and offsite. Increased machine utilization and reduced operator fatigue would result in this scenario and lead to productivity gains. This could enable more access to timber at a lower cost.

Reducing working fatigue and enabling operators to work offsite in a safe and comfortable environment would also make operator positions more attractive to new workers and could extend the career of existing operators.

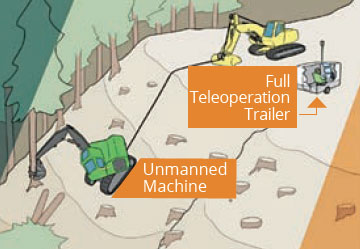

It also increases the safety. For instance, operating harvesting machines on steep slopes is hazardous since the steep pitches cause machine instability. This increases the risk of the operator losing control of the machine and potentially causing serious injuries and costly machine damage. By removing the operator from the machine, these risks are mitigated.

Video screen of teleoperated Caterpillar feller buncher. (Courtesy of ARA)Teleoperation requires human-machine interaction using advanced autonomous navigation, machine sensors, and sophisticated communication protocols. Some of the challenges to implementing this technology include developing a robust communication system, improving productivity, reducing ownership and operating costs, integrating teleoperation with winch assist technology, as well as finding early adopters.

Video screen of teleoperated Caterpillar feller buncher. (Courtesy of ARA)Teleoperation requires human-machine interaction using advanced autonomous navigation, machine sensors, and sophisticated communication protocols. Some of the challenges to implementing this technology include developing a robust communication system, improving productivity, reducing ownership and operating costs, integrating teleoperation with winch assist technology, as well as finding early adopters.

Development of teleoperation technology in forest operations

Applied Teleoperation Limited (ATL) (New Zealand) and Applied Research Associates (ARA) (U.S.) have developed teleoperation systems for forest operations. These systems allow an operator to remotely control harvest machines from an onsite trailer. There are also several other teleoperation technology providers that are currently developing virtual reality-based technologies that may be applicable to harvesting machines. However, the technology still needs further refinement to meet the requirements of the Canadian forest sector.

Lead the initiative and pilot teleoperation in the Canadian forest industry!

Virtual reality-based teleoperation of forwarder (Courtesy of Skogforsk’s Troëdsson Forestry Teleoperation Lab)FPInnovations has identified winch-assisted skidders as the most feasible entry-point for the implementation of teleoperation technologies in Canadian forests due to the relative simplicity of operations compared to other harvesting phases (e.g., feller buncher, harvester, etc.). If this is proven successful, then teleoperation could be adopted by other machines, such as feller bunchers or loaders, and possibly in equipment used at mills.

Virtual reality-based teleoperation of forwarder (Courtesy of Skogforsk’s Troëdsson Forestry Teleoperation Lab)FPInnovations has identified winch-assisted skidders as the most feasible entry-point for the implementation of teleoperation technologies in Canadian forests due to the relative simplicity of operations compared to other harvesting phases (e.g., feller buncher, harvester, etc.). If this is proven successful, then teleoperation could be adopted by other machines, such as feller bunchers or loaders, and possibly in equipment used at mills.

Early adopters of these technologies stand to gain from reduced operating expenses through better machine availability and being at the forefront machine design improvements and modifications. A pilot study of teleoperated skidders operating on steep slopes in Canada is proposed to determine the feasibility of teleoperation technology. An incentive program could be developed to offset some of the financial and operational risks for the participating contractor. Key technology providers have been identified, and life cycle requirements such training, parts availability, and technical support could all be examined within this pilot program.

Logging contractors and forest companies in Canada interested in piloting the teleoperation in their operations are invited to contact Mithun Shetty, Senior Researcher, at

Source: FPInnovations