The paper industry, long recognized as an energy-intensive sector, is now at a crucial turning point. As Europe aims for carbon neutrality by 2050, paper mills face an unprecedented challenge: electrifying their production processes to drastically cut emissions and maintain competitiveness.

In an industrial landscape increasingly prioritizing sustainability, this shift is more than just an environmental goal – it is an economic and regulatory imperative that is actively reshaping the future of this key sector.

This is not merely a voluntary choice, but rather a mandate from Brussels. The European Green Deal and the Fit for 55 package leave no room for interpretation: the goal is to reduce CO₂ emissions by 55% by 2030 compared to 1990 levels, alongside a gradual phasing out of fossil fuels. Papermaking companies are now compelled to make a definitive shift, as they accelerate their transition toward fully electric technologies and significantly reduce their reliance on natural gas and other fossil fuels.

In this context, Toscotec is further establishing itself as a pioneering company. It offers technological innovations to guide clients in the transition toward zero-direct-emission plants. With a strong commitment to Research and Development, the company provides a wide range of cutting-edge and flexible solutions, ideally suited to support the partners in achieving their sustainability objectives.

Details of the Toscotec full-electric batteries in Fortissue.

Details of the Toscotec full-electric batteries in Fortissue.

Toscotec's R&D department bases its strategic approach on three main pillars: sustainability, reliability, and flexibility. First, it is key to ensure a tangible and measurable reduction in emissions by directly implementing technological changes within the mill. Second, Toscotec is committed to integrating new electrified technologies into production cycles with the same reliability as traditional solutions. Finally, the third pillar addresses the biggest challenge: designing machinery and systems capable of operating in various energy environments, whether in hybrid or full-electric mode, to meet the specific needs of each production site.

Field data from operational plants directly guides development and fosters a continuous feedback loop between engineering and real-world performance. Software-automation integration is another key area of focus. Our thermal control algorithms are precisely calibrated to respond in a predictive manner to load fluctuations, significantly reducing waste and improving product quality.

In addition, Toscotec cooperates with universities and European research centers on joint industrial decarbonization projects. This not only aims to develop new technologies but also strives to validate their impact in terms of ROI and TCO.

Toscotec and Fortissue: start-up day.

Toscotec and Fortissue: start-up day.

Fortissue, in Portugal, is now considered a European model for the green energy transition within the Tissue paper industry. This mill, entirely designed, installed, and started up by Toscotec, stands as the first fully electric, industrial-scale Tissue paper mill. It functions without the need for direct on-site combustion; thus, it paves the way for a cleaner future in papermaking.

All systems within the Energy & Environment Department are powered by electricity, with an optimized configuration designed to leverage local renewable sources and drastically cut CO₂ emissions. Fortissue serves as a real-world, open-air laboratory. The rebuild project, through our Energy Pack products, allowed us to successfully test and demonstrate the immense potential of electrification within the industry.

Equipped with Toscotec’s TT NextPress shoe press, this high-performance machine has been upgraded completely to make tissue production more sustainable. We installed a fully electrical air system configuration through the TT e-powered Hood (with natural gas burners remaining for backup), featuring multiple heat recovery stages. TT Swing ensures maximum flexibility, as it offers a variety of choices from full cascading mode to hybrid configuration, depending on specific production needs. Meanwhile, TT Turbodryer utilizes a portion of the hood exhaust gases to enhance the shoe press's effectiveness and increase water removal during pressing. Finally, the new TT e-powered SteamBooster generates 100% of the steam required for the TT SYD Steel Yankee Dryer. A significant portion of this steam is recovered from the hood exhaust heat, with the remainder generated by electric heaters.

The Portuguese plant's success proves how thorough thermal flow engineering, combined with digital integration, enables performance that rivals – and in some instances even surpasses – that of conventional plants. For example, the absence of a chimney for the electric boiler immediately yields approximately a 10% saving. The hood can also achieve consumption reductions due to the absence of combustion air. This project served as a powerful market benchmark, which demonstrates that the electric papermill is no longer a distant, futuristic idea, but a concrete and competitive reality today.

Another significant example comes from a recent turn-key plant supply in France, where a complete tissue plant featuring new-generation electric hoods from Toscotec was recently commissioned by MPH1865. This represents a forward-thinking strategic choice, which offers lower environmental impact, total control over energy costs, and alignment with future decarbonization policies.

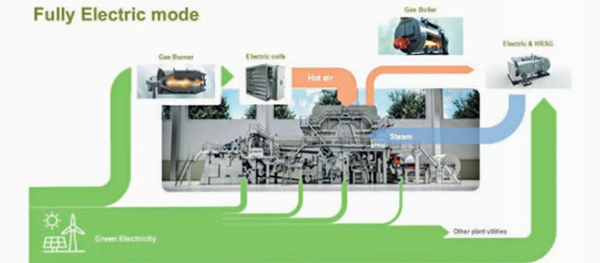

Scheme of the full-electric configuration.

Scheme of the full-electric configuration.

The electric hood installed at MPH1865 stands out for its high efficiency and ability to dynamically adapt the drying curve, with the future potential to leverage the control system's predictive intelligence. This results in consistent product quality and a significant reduction in specific thermal energy consumption. Furthermore, the supervision interface allows for real-time monitoring of energy parameters and demand response activation strategies during peak periods on the electrical grid.

The projects at Fortissue and MPH1865 are no longer exceptions; they now serve as benchmarks for future installations. Interest in full-electric solutions is clearly growing, driven by public incentives, increased availability of renewable energy sources, and progressively stringent sustainability policies from major retailers and end-users alike.

Toscotec stands out as more than a technology supplier — it is a strategic partner in the paper industry’s decarbonization journey, providing a fully integrated approach to energy transition. The company’s current focus is on scaling up these innovative solutions to make them replicable and economically sustainable, while maintaining the industry’s essential standards of quality, competitiveness, and production continuity.

About the Author

Francesco Ureni, Head of R&D

Francesco Ureni, Head of R&D

Francesco Ureni is the Head of R&D at Toscotec. His career at Toscotec began in 2011 after he obtained a master’s degree in chemical from the University of Pisa. Francesco's expertise spans process optimization, commissioning, and start-up management, having held various roles at Toscotec, including Associate Chief Customer Service Officer, Plant Optimization Manager, and Senior Process Engineer. With over a decade of experience at Toscotec, Francesco continues to drive innovation and excellence, leading the R&D department.

About Toscotec

Founded in 1948, Toscotec specializes in the design and manufacture of turnkey projects, complete machines, rebuilds and stand-alone systems for the Tissue, Paper and Board, and Nonwovens industries. Headquartered in Lucca, Italy, with subsidiaries and service centers in China and North America, Toscotec offers cutting-edge technology and customized solutions to paper producers around the world. Its technology is designed to achieve high production efficiency, low energy consumption, and the highest product value. From April 30th, 2020, Toscotec is part of the Voith Group.