The paper and packaging industry is facing major challenges: raw material prices, energy costs, environmental regulations and ongoing competitive pressure demand mills that are both efficient and adaptable to ensure sustainable profitability.

Strategic site development forms the basis to design future proof new mills and expansions or modifications of existing sites.

"Site development is a long-term process. It begins with a view of the entire site and all development phases of a paper mill," explains Peter Oksakowski, Managing Director of BHM INGENIEURE. “Whether it's a new mill or the development of an existing site - the design approach must be tailored to the specific case.”

BHM INGENIEURE, based in Austria, has been supporting paper manufacturers as an overall engineering and consulting firm for more than three decades - both in the development and design of new plants and in the structured development of existing production sites.

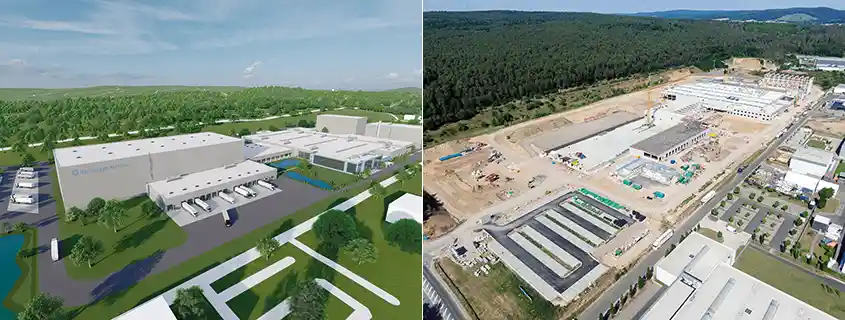

Greenfield projects: future proof from day one

The design of new paper mills and box plants begins with the choice of a suitable plot. Key factors such as land dedication, plot geometry and size, sufficient energy and water supply, subsoil conditions, connection to the public road and railroad network, availability of labor, as well as the legal framework and public subsidies, play a decisive role here. Greenfield projects allow for optimal alignment of buildings, infrastructure, logistics and process equipment by applying an integrated design method. This design approach also focuses on the site’s potential for long-term development.

Key tasks in the site development process for new mills:

- Checking the basic suitability of the site

- Definition of the project and any future expansions

- Clarification of the necessary permits and possible legal restrictions

- Determination of the expansion phases

- Reviewing the impact of the structural implementation of the individual expansion phases on ongoing operations

- Ensuring dimensioning of utilities, taking expansion phases into account

- Conceptual solutions about intralogistics

- Development of a traffic concept

- Preparation of rough cost estimate

“In order to avoid mis investments, site development is of crucial importance when designing a mill,” says Peter Oksakowski. "All expansion stages must already be taken into account. This can prevent cost-intensive demolition works, modifications, and disruptions to ongoing operations in case of future expansions. Ultimately, the plant should meet all the requirements needed to implement modern intralogistics solutions and ensure efficient production processes, in all intermediate stages and in the final expansion."

Existing plants: optimizing a running system

The challenges are different for plants that have grown over time. Many paper mills and box plants have been expanded over decades without an overall concept. In numerous cases, there is insufficient as-built documentation of the buildings or no up-to-date drawings concerning underground utilities and outdoor facilities. This is an enormous challenge for design, as these basics are absolutely essential for conversions or extensions to the mill. Correctly recording the existing situation and creating as-built plans with the help of 3D scans is quite time-consuming for production buildings, despite modern technology, due to the presence of process equipment, pipework, tanks, and cable routes. Creating plans from the point cloud requires a great deal of experience in order to obtain a result that can be used as a basis for further design.

The following aspects are particularly important in development of existing sites:

- Recording and evaluating the existing building and pipeline inventory

- Ensuring adequate media supply and disposal

- Identification of intralogistical weak points (e.g., insufficient storage space, insufficient throughput of storage systems, excessively long transportation routes)

- Development of realistic conversion and expansion scenarios

- Ensuring production capability during all construction phases

- Checking the approvability of changes to existing buildings and expansion projects.

“With existing plants, the challenge often lies in implementing expansions under cramped conditions and during ongoing operations,” explains Peter Oksakowski. “Here it is particularly important to consider infrastructure, logistics and supply in context.”

Integral design method as the key to success

The early involvement and coordination of all project partners is a key success factor for both new builds and the development of existing sites. As an overall designer, BHM INGENIEURE takes on the interdisciplinary design of all specialist areas.

"The advantage for the client lies in the integral design approach, as well as the fundamental understanding of the production processes and the requirements of intralogistics in the paper industry. This allows us to identify technical and logistical dependencies as early as the project development stage and take them into account during the implementation phase," says Peter Oksakowski. “This reduces risks, speeds up processes and creates transparency in all phases of the project.”

A key component of integral construction design at BHM is the use of Building Information Modeling (BIM). The model-based working method makes it possible to combine all disciplines of construction design, process design and intralogistics design in one digital model. BIM is indispensable for design coordination, especially in complex industrial projects with numerous participants.

"The BIM design method has many advantages: Better integration of all project participants in the design process, efficient design coordination, early detection of design conflicts and clearly defined design standards are the basis for a successful project," emphasizes Peter Oksakowski.

In the paper industry in particular, where construction, plant technology and intralogistics are closely intertwined, centrally coordinated site development ensures solutions that balance future viability, cost-efficiency, flexibility, and sustainability – whether for new builds or the restructuring of existing sites.

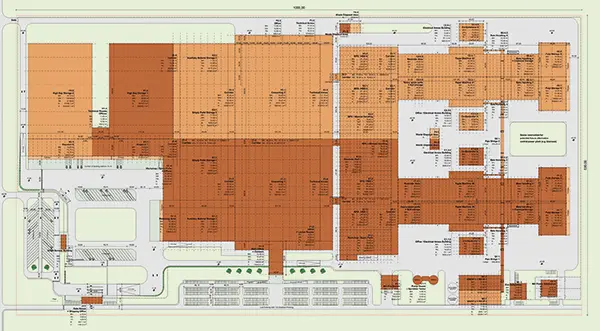

Example of a Site Development Plan (SDP) of a tissue mill to be realized in different phases, the dark color showing Phase 1, the light color Phase 2. © BHM

Example of a Site Development Plan (SDP) of a tissue mill to be realized in different phases, the dark color showing Phase 1, the light color Phase 2. © BHM

Conclusion

Site development provides a systematic framework for aligning paper mills and box plants with future requirements. While the strategic structuring of the entire plant and its expansion stages is the primary focus in new construction, the emphasis for existing plants lies in integrating new requirements into historically evolved structures. In both cases, the following applies: those who create holistic design perspectives at an early stage reduce risks, costs, and operational restrictions in the long term.

“Sustainable paper mills are not the result of spontaneous individual measures,” summarizes Peter Oksakowski. "They are the result of well-considered site development - with a clear strategy, realistic goals and reliable implementation. Integrated site development is the first and most important step for a successful project."

About BHM INGENIEURE

BHM INGENIEURE is an Austria-based engineering and consulting firm specializing in integrated planning for industrial and infrastructure projects. With over 30 years of experience, the company supports the paper and packaging industry in designing new mills, expanding existing sites, and implementing sustainable, future-oriented solutions through its interdisciplinary and BIM-based approach. https://www.bhm-ing.com/en/